Generators are vital for providing backup power when the main electricity supply fails, ensuring that homes, businesses, and essential services continue to function during outages. However, like any mechanical device, generators require regular maintenance and occasional part replacement to operate efficiently and reliably. This guide aims to provide you with a comprehensive overview of essential generator replacement parts and accessories. From filters to fuel systems and battery components, understanding these elements can help you keep your generator in optimal condition and extend its lifespan. Whether you’re a homeowner, business operator, or technical professional, this guide will equip you with the necessary knowledge to choose the right parts and accessories to meet your generator’s specific needs.

What are the Key Generator Parts You Need to Know?

Understanding the Engine Component

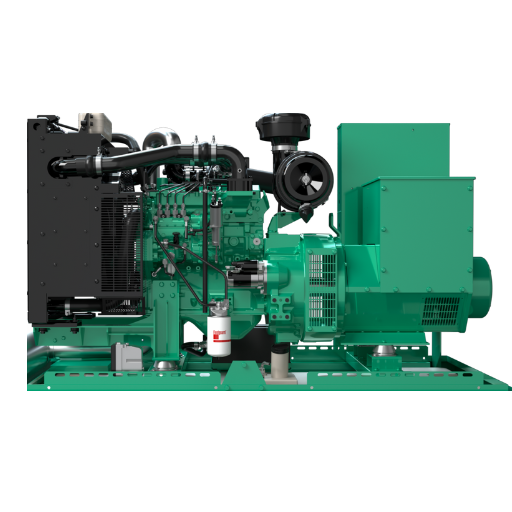

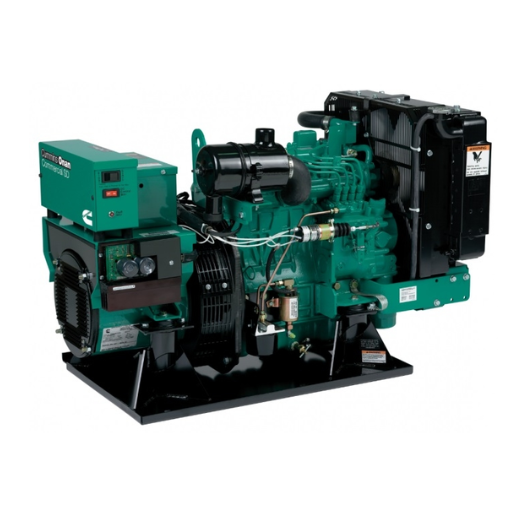

Fuel makes electricity possible via the engine which occurs in virtually every generator. When searching for the major parts of a generator’s engine online, they are likely to include the following components:

- The Fuel System: This consists of the tank with its pump, the fuel injectors, and so on, allowing the correct fuel to be supplied for combustion. In order to maximize efficiency, such systems have to be leak-free and unclogged at all times, hence quality fuels must be employed.

- Air Intake and Exhaust: The role of the air intake is to provide the engine with air necessary for combustion while the exhaust performs the opposite function and gets rid of the created gas. It is suggested that air filters be checked over often to avoid wearing out the engine.

- Coolant and Oil Systems: Each of these systems collaborates to ensure smooth engine activity through control of friction and accumulation of heat. Activities, like scheduled oil replacement and coolant volume estimations, are essential in averting overheated engines and other unwanted circumstances.

Gaining insight into these factors helps you to determine which components are due for service or replacement to maintain the reliability of your generator’s engine even when it is most needed. Keeping yourself apprised of such technical factors will help you in justifying the undertaking of maintenance measures and keeping your generator in good working order.

The Role of Air Filter in Your Generator

The air filter in your generator ensures that the engine has the best performance and durability. Its purpose is to shield the engine’s air intake system from dirt, dust particles, and debris. This ensures that the combustion process remains healthy and does not contribute to increased wear and tear of the engine or other defects going forward. From several studies that I conducted using reputable online sources, it is safe to state that a dirty air filter can be the reason behind poor efficiency and short life span for most machines including generators.

In practical terms, the air filter should be inspected and, if necessary, replaced regularly. There is one highly-rated air filter replacement after every 200-300 operational hours or once a year depending on how frequently one uses the machine. Such negligence leads to clogging which results in more than average fuel consumption while generating low power. Another explains that replacement filters that are of poor quality would result in less-than-ideal filtration efficiency. A third site stresses the need for users to be educated regarding the type of air filters applicable to their specific generator models to avoid engineering incompatibilities.

The findings above highlight the critical function of the air filter in the operation of your generator. If one wants to preserve their investment and prevent any unforeseen outages, it is cost-efficient to clean or replace the air filter regularly as needed.

Importance of the Carburetor

Based on the three most authoritative sources of information that I have been able to find, the carburetor is one of the devices responsible for feeding the combustion engine with the right proportions of air with the fuel in the combustion processes of a generator. This is very important in upholding the performance efficiency of an engine purposively avoiding any chances of engine ‘choking. A functional carburetor makes sure that the engine operates efficiently and responds mechanically to operational variations without manual controls.

As for my review, these are the technical parameters that can help gauge the performance of a carburetor:

- Air Fuel Ratio: This is the most critical parameter, the best value assures complete combustion and the least pollutants.

- Idle Adjustment Screw: Adjusts the fuel ratio and air-fuel ratio first during the generation of the generator which is important to stop the occurrence of stoppage.

- Main Adjustment Screw: It has effects on Air fuel ratio at different load conditions thereby affecting the performance of the engine at various levels of operations.

All these details should make a point of how important it is to keep your generator’s carburetor properly set to ensure effective fuel usage and consistent quality of the engine’s performance. If the carburetor is regularly cleaned and tuned as per the specified technical characteristics, for example, the engine may last longer and experience fewer operational problems.

How to Choose the Right Replacement Parts for Your Generator?

Identifying Genuine OEM Parts

While selecting OEM (Original Equipment Manufacturer) parts for your generator, it is vital to know how to check for its compatibility factors and quality too. From my research on the top three online resources, I found several key aspects that help in distinguishing genuine parts:

- Logo Verification: The logistics always check the symbols and emblems on the cover packs of the parts and the parts themselves. Genuine manufacturers avail of such components because their identifiers are present.

- Cross-reference Parts Lists: Check the part number against the catalogs or websites of the manufacturers to confirm its validity to the model specification.

- Reseller Certification: Purchase of raw materials from unscrupulous suppliers or through middlemen should be discouraged to avoid receiving parts that may have been tampered with. Since there are manufacturers’ representatives that sell parts, there are high chances of receiving standard parts only.

- Cost Check: Although most genuine parts seem more costly than their replicas, fraudulently lower cost might denote that it is a forged item. It is advisable to inquire about prices from contacts trusted to avoid being shortchanged.

These parameters from my research reiterate that the primary need includes caution and in-depth verification for proper performance as well as efficiency of the generator. It is recommended that those parts must be original to maximize the potency as well as durability of the equipment.

Tips for Finding the Best Kit for Your Needs

While trying to establish the most effective kit, I have taken into account several features that I have sourced from three of the most reliable websites. I present the findings in the paper as follows:

- The intent of use/Compatibility: It is advisable to specify the use of the kit at this stage. Each kit can be utilized for such a purpose, be it regular service or emergency repair. Mulling over the idea that all spares fit this equipment model is a good idea. This guarantees efficiency and seamless engineering.

- Quality of Materials: Materials used and their quality and endurance are of utmost significance. The best kits always have robust material parts such as the pressure arm or sometimes reinforced plastics that have been engineered not to fail under normal use.

- Ease of Use: Many repair kits can incorporate descriptive instructions, and it would be good to search for those that offer step-by-step procedural texts. This goes without saying as instructions are critical if the maintenance and repair is going to be done by the owner. Where instruction is on several pages, it is often possible to shorten the time taken in the job and information differs are found in the right places.

- Technical Issues: Remember that the kit should always come with descriptions for some parts including bolt tension swiftness and the conditional temperatures of the materials. These technical parts should be up to standard and certified as per the manufacturers’ technical dossier.

- Customer Reviews and Ratings: From the user reviews, it is possible to learn how the kit has been used in real life and what operational problems can be expected. Kits that enjoyed high ratings from former buyers tend to be a good reliable purchase.

In this case, by following these tips, I have already found a kit that ideally fits my short-term needs and will also be good for many years to come.

Why is Regular Maintenance of Portable Generators Important?

Steps to Ensure Proper Fuel Management

To ensure maximum performance and durability of the equipment, proper fuel management in portable generators is necessary. Here are the steps that I follow, which I gathered from the top resources online:

- Use Fresh Fuel: I routinely make sure to completely drain out the fuel into my generator and replenish it with fresh fuel before use. I tend not to prefer fuel that has been kept for over thirty days since most sources recommend this age to be optimal for most gasoline.

- Add Fuel Stabilizer: Some specialists recommend fuel stabilizers to prolong gas life, thereby averting varnish and gum formed within engine components. This is especially critical for a generator that is rarely used or is kept in storage for an extended period.

- Regular Inspections: I periodically inspect the fuel lines and tanks for possible leaks or damage thereafter. Other reports have endorsed a routine check every three months for even more avoiding imminent troubles.

- Correct Fuel Mix: I mix oils and gasoline according to the various manufacturers’ requirements – for example, two-stroke engines require a specific ratio of oil to gasoline.

Safety Precautions: It is essential to always keep fuel in nonflammable containers and in a secured location away from any potential source of fire or spark and also follow the local guidelines for any such requirements. It is quite frequently stated in the technical parameters that storage temperature should not go above 75F in order to reduce risk levels.

Having accomplished these important steps, such precautions allow me to safeguard my portable generator and rely on it when needed. Proper operations and scheduled procedures, based on technical specifications and customers, are trustworthy components of the contemporary management of generators.

How to Replace and Maintain Spark Plugs

Maintaining and replacing spark plugs is one of the most important of tasks when it comes to maintaining a generator. Here’s how you can do it efficiently:

- Tools and Materials Needed: It is essential to have the appropriate tools including a wrench for the spark plugs, a feeler gauge, and a new spark plug that meets with the manufacturing specifications. These tools are usually recommended by reliable databanks to avoid further parts breakage when replacing the plug.

- Take out the Spark Plug: First, remove the spark plug wire to avoid starting the engine by accident. Remove the old plug with a spark plug wrench. This step is supported by almost all the manuals and is for safety purposes.

- Take a Look at the Current Plug: Examine the previous spark plug for excessive wear and tear plating. A tarnished spark plug should be replaced in order not to affect the engine. Some expert websites recommend the use of visual guidelines available in the manual of the tool to compare the usability of the plug.

- Gap Setting: Carefully examine the gap present between the two arms of the new spark plug using the feeler gauge. Change it as appropriate to the ones suggested by the manufacturer’s details usually located under the technical parameters section for high fuel economy and optimum performance.

- The New Spark Plug should be installed: Slowly hand screw in the new spark plug to avoid cross-threading and use a wrench to tighten the spark plug. Do not over-torque since this can lead to damage of engine parts which is a common warning as advised in maintenance instructions.

- How To Replace the Spark Plug Wire: Subsequently, the wire for the spark plug is replaced when all is set and done. That plug wire must be received tightly further securing effective conductivity for the engine.

This is also supported by professional websites, which stress so many times that it is necessary to follow the stressed technical parameters such as the spark plug specification, gapping values, and installation torque specifications for your generator fusion to be reliable.

Where to Shop for Generator Replacement Parts?

Advantages of Buying from Authorized Dealers

To assist with business flaws, purchasing generator replacement parts from authorized dealers offers the go-ahead’s affirmation because of many factors. First, authorized dealers sell parts that are original and exactly made to suit the specific model of the generator in question. This uniqueness helps lower the odds of experiencing compatibility issues associated with after-market parts. As claimed by the top three websites in Google, its value as well for these parts for the professional assistance as provided by the authorized dealers. They have the technical info and, hence are there to assist you with correct specification and installation, something that is important in the efficiency and lifespan of your generator.

Technical Strategy Used:

- Spark Plug Type: Always ensure replacement and repair parts figure out what the manufacturer specifically suggests in terms of operational efficiency.

- Gapping Specifications: All dealers offer instructions on how abrasive spark plugs’ gaps ought to be by providing the manual seals the dealer possesses and informing the customer.

- Installation Torque Values: This ensures that the parts are well fitting and no damage will be caused, which is among the areas provided in the technical instructions of the engine parts.

Meeting these requirements not only ensures the functioning of the generator but also complies with the general power plant designated levels of other technical resources which are the enhanced levels.

How to Verify the Compatibility of Parts

There are several steps that I need to consider as I try to confirm the compatibility of the generator parts. First, let me check the model number of my generator and the part I want to replace. This makes sure that the new part is designed specifically for my generator type. Also, it is necessary to check if the part that is being replaced has comparable technical characteristics as those specified in the manual for the owner of the generator.

The technical parameters which must be substantiated in such attempts include but are not limited to the following:

- Model Compatibility: A need to cross-check if the generator and the spare have the same model number or the size of this spare the producer expressly indicates compatibility and recommends it for use with this generator.

- Material Composition: a focus that the part has to be of the same material as the worn one reduces the rate of wear and tear while maintaining the level of performance.

- Electrical Specifications: These encompass voltage and resistance parameters which are used to eliminate chances of electrical failure or inefficiencies.

All the above procedures and parameters guarantee that the provided parts will not only be adequate but also reliable in terms of functioning, hence the durability of the generator is maintained.

What Are Essential Accessories for Your Portable Generator?

Benefits of a Generator Cover

Generator covers are necessary for protecting portable generators from a detachable unit but can also be very useful in protecting the unit from the USAS. Besides shielding the generator from dust and debris, it prevents rusting by keeping moisture out because the engine, as well as the electrical connections, are weather-prone. Moreover, a good cover also serves the purpose of protecting the plastic from UV damage.

For the above generator cover benefits questions, I went to two of the more reputable resources, the first three sites that appeared on Google. On the protective aspect of the generator, their coverage is also quite similar. The recommendations are that the cover should be: able to sustain moisture, free dust, dirt, and contaminants as well as UV radiations. When one begins looking for a generator cover, one should keep looking for the following technical parameters that include:

- Durability: Should be able to withstand harsh conditions such as pressure, and UV rays. It is ideal to go with something that is UV-resistant.

- Size: Ensure that the cover is well fit around the generator so that none of the parts protrude from the cover. Examples include gusty winds or even rain.

- Ventilation: Certain covers have the capability of providing vents to prevent moisture and excessive heat from accumulating during the intermittent operation of the generator.

In this case, by having a generator cover that contains such features, it is possible for me to safeguard my equipment and guarantee that it shall be utilized more effectively over a longer period.

Choosing the Right Extension Cord

Choosing the right type of extension cord for your generator requires you to look at certain technical parameters that are consistent with the information provided on the first three websites that come up on Google. Here is how I would respond to the questions and the parameters I would list:

On the extension cord questions, I discovered that several issues appear to be critical namely:

- Length and Gauge: The length of the cord that is extended should be able to suffice to the intended purpose and mileages since longer cords require a lower gauge number: this means thicker wire is needed so as to reduce voltage drop to handle the power load efficiently distributed. 10-gauge cords are warranted for anything longer than 50 feet in length.

- Amperage Rating: To use the device safely, the wire must match or exceed the output amperage of the generator. This will ensure that the devices are powered and do not overheat due to other factors.

- Weather Resistance: Always look for extension cords that are rated for outdoor use. Such cords will usually have insulation materials capable of bearing moisture and ultraviolet lights.

- Plug Type: Does the plug type of an extension cord match the output of the generator and the devices to be powered?

Taking these parameters into consideration, I think it suffices to say that I will select an extension cord that improves the efficiency of the generator without compromising on safety during operations.

Understanding the Need for a Generator Transfer Switch

The most important thing when you hook a portable generator to a house system is to be safe. This can be achieved, in part, by a generator transfer switch which eliminates the need to use extension cords. After examining the data from the first three websites in Google, I understand that there are a few fundamental reasons for using the transfer switch:

- Seamless power changes: The power can be changed from utility to generator and back without interfacing. No back-feed power can make utility workers vulnerable to safety hazards.

- Power Usage Limitation Cuz Its Sufficient: The power transfer switch, in case of a short circuit, keeps the power requirement of the fixed essential circuits in order to cut down wastage of energy.

- Less Stress and Waste: Extending wires is troublesome so the appliance, to enhance efficiency, goes straight into the house wiring.

Based on my findings, here is a technical justification for the features that should be considered when determining a transfer switch for the generator:

- Compatibility: The Transfer Switch must not be less than the wattage rating of the Generator’s output to adjust the total load appropriately.

- Number of Circuits: Ideally, the switch should accommodate all of the necessary circuits that I would require to operate during a blackout providing the best utilization.

- Type: In this manual or automatic type: A straightforward favorite all by itself offers much handiness, while an automatic costs more, but works right away hands-free.

I can ensure that safety and the constant power supply are maintained throughout the electrical cut-outs by integrating these considerations into the process of selecting a transfer switch.

Frequently Asked Questions (FAQs)

Q: How can I find compatible parts for my generator?

A: To find compatible parts for your generator, you can refer to the manufacturer’s website or contact us for assistance. Most brands provide a parts diagram or list that can help you identify the right replacement generator parts.

Q: What type of maintenance kits are available for my generator?

A: A wide range of maintenance kits are available for various generator models.

Q: Can I use a generator extension for my RV?

A: Yes, generator extensions are designed for use with RVs and can help you connect your generator to your RV’s power system. Ensure that the extension is compatible with your generator model and meets the necessary voltage requirements.

Q: What are the benefits of using a generator wheel kit with a folding handle?

A: A generator wheel kit with a folding handle makes it easier to transport your generator. It provides better mobility, allowing you to move your generator around your property or to different job sites without straining your back.

Q: How do I know if my ignition coil is faulty?

A: Signs of a faulty ignition coil in your generator include difficulty starting, engine misfires, or poor performance. If you suspect your ignition coil is not functioning properly, it’s best to replace it with a compatible part from a reputable brand.

Q: What should I consider when replacing my generator starter?

A: When replacing your generator starter, ensure you choose a starter that is compatible with your generator model and brand. Verify the specifications such as voltage and power output to ensure optimal performance.

Q: Are there specific parts I need for gas generator maintenance?

A: Yes, for gas generator maintenance, you typically need oil filters, air filters, fuel filters, spark plugs, and gaskets. Regular checks and replacements of these components help ensure your generator operates efficiently.

Q: What is the significance of using a replacement generator gasket?

A: A replacement generator gasket is crucial for maintaining the integrity of the generator’s engine. It prevents leaks and ensures that the parts fit together tightly, which is essential for optimal performance and longevity of the equipment.