When it comes to powering your home or business during an outage, a Generac generator is a trusted solution. However, maximizing its potential often requires delving into specific features and codes that can enhance its performance and reliability. This blog aims to demystify the workings of your Generac generator by focusing on essential dealer codes, maintenance tips, and operational insights. We’ll explore the significance of these codes in troubleshooting and maintaining your generator, ensuring it runs efficiently and effectively when you need it most. Whether you’re a seasoned owner or new to generator usage, our comprehensive guide is designed to equip you with the knowledge and tools necessary to unlock the full capabilities of your Generac system.

What is a Generac Dealer Code and Why is it Important?

Understanding the Basics of Generac Codes

As I searched for the most reliable generators, I came across sources on Generac dealer codes which were invaluable in tremendously aiding in maintenance and troubleshooting. These codes are usually related to some fault or operational state of the generator which assists the users or technicians in locating and fixing the problem quickly. One major point picked from these resources is that users need to know the importance of their model and serial number as these codes are model-based.

One of the additional important components is knowing for which codes you should call a repairman right away and which are simply due for a scheduled checkup. Standard codes, for example under or overvoltage, have a standard quantity associated such as voltage ranges and frequency norms which are to be referred together with the manual of the generator so as to ensure that these figures are within the normal operating parameters of the machine.

These quotes also from other remarkable sources explain and emphasize that a complete understanding of dealer codes is not only important in regard to effective operational use but is also important in the longevity of your generator. Never forget the rule that every time try to have these codes available because they are key when it comes to having a smooth operation of your Generac system.

How to Access the Dealer Menu Using Your Code

To navigate the dealer menu using your Generac dealer code, please complete the following steps:

- Locate Your Control Panel: Start by looking for contact locations on your Generac generator. It is often located in the generator interface zone and the user will be dealing with the generator.

- Enter Dealer Code: When the control panel is on, the user needs to enter the dealer code which is given uniquely to him/her. This code is particularly necessary to be able to enter the dealer menu and other more complex settings. The dealer code is provided in connection with the user manual within the generator device or by an authorized Generator dealer.

- Navigate to Dealer Menu: After typing in the code, please and now use the control panel of the generator to navigate and click on the dealer menu option. This section will allow access to a lot of functionalities such as diagnostics, setup, and maintenance mode features of the system.

While investigating the first three websites, the technical parameters required for accessing and use of the dealer menu specifically include the model number and serial number of your generator since these may influence the codes and options given. Constant voltage and frequency settings understanding is also essential since the wrong ones can disrupt the operations. The user should refer to the machine manual of their generator to rationalize any alterations done on the menu to promote compatibility with the generator specifications and operating instructions.

Common Issues with Dealer Codes and Solutions

As one of the users dealing with the dealer codes, some challenges could be encountered that will affect the accessibility and usability aspect of the Generac system. For instance, one of the issues is caused by users entering the wrong code thus restricting themselves in the dealer menu. In addressing this, it is critically important that one is keen while inputting the code by the user manual. There are issues related to the dealer code about the model number of the generator which might lead to code mismatch. In such situations, it may be important to check the model of the machine and make sure that the appropriate code is obtained from the certified dealer.

Last but not least, when carrying out changes that are to be made using the dealer menu, it is also very important to pay attention to the technical parameters such as voltage and frequency settings. Wrong generator settings can impair the generator’s functioning. Consequently, it is advisable to refer to the user guide or seek the opinion of a technical expert. In addition, every time, it is necessary to confirm that the generator’s operational parameters are not violated while introducing the changes.

In response to your request for assistance and my knowledge of top resources, I would like to emphasize that it is important to be accurate and concentrated as one works with the dealer codes and troubleshoots the problems. It is recommended to ascertain the triangulation of the model, serial, and dealer code as very fundamental. In case you have more queries on the subject, do not hesitate to pose them, as I shall provide detailed instructions.

How Can I Troubleshoot Generac Generator Errors?

Steps for Generac Generator Troubleshooting

- Initial Diagnostics: When trying to repair your Generac generator, first look at the control panel. Check for any error codes or warning lights that may be visible on the control panel. These characters have meanings as well which can be found in the user manual. Determining an error code usually helps because it identifies the problem – be it low oil levels, electrical faults, and so on.

- Check and Confirm Fuel Supply: It is critical to check that the generator has enough gas. Operational failure is quite a common problem. Check the fuel tank to see if you can find sufficient fuel levels. Another option would be to check the fuel lines for possible leaks or blockages.

- Inspect Battery and Connections: Problems with the battery or the connection of certain wires can be reasons why the generator does not work. Make sure that the battery has been charged and that the terminal wirings do not have any rust in their connections.

- Examine Air Filters and Oil: Consider the condition of air filters next. If the filters are clogged, they will prevent the engine from reaching its optimal performance. Change or clean the filters as per the instructions. In addition, evaluate the amount and the quality of the oil and replace it where necessary for maximum performance.

- Technical Settings: First, make sure to always check the voltage and the frequency parameters of the generator before tweaking any of its settings. Such settings ought to be modified with broodness and in accordance with the regulations of the manufacturer. Factors such as the output voltage voltage considering target level (say 120/240 volts for home use units) and rated frequency of the equipment (usually 60Hz) should be taken full control of.

As I understand from the best-known sources, working with dealer codes or technical diagnostics is not a seat of leisure but requires one concentration. There is also the need for adjustments to be accompanied by a good representation of the model and serial number with the code and settings of the generator in as far as improving the performance of the instrument is concerned.

Exploring the Repair Forum for Solutions

Consulting a repair forum can be helpful in diagnosing generator-related problems. As I’ve examined the first three sites of google.com’s content, I’ve gathered additional useful information that aids in effective coping strategies.

- General instructions: Many experienced unfamiliar people must turn to a complete check of the generator’s fuel system, oil, and electrical system. Checking each of these components beforehand could eliminate many simple functional troubles as well.

- Investigation of Technical Parameters: Consider checking the voltage and frequency settings as needing reporting in this section. The household generators of most homes need to provide a voltage configuration of 120/240V and a frequency of 60Hz. Such readings should be the same as those indicated by the manufacturer in order to avoid deviations in performance.

- Battery and its connections: One of the common recommendations is to keep the battery terminals as well as the connections tight to avoid superfluous electric defects.

To sum up, the repair forum suggests there should always be a step-by-step approach in seeking for the specific fault. These materials, in particular, technical specifications, assist me in effectively and safely rectifying the faults of a generator.

When to Contact a Generac Dealer for Service

It is very important to contact a Generac dealer for service, Only when the need arises as such, knows, are the signs. What follows is a set of instructions that I formulated following insights from the first three google.com default pages:

- Recurrent Mechanical Problems: Once I do a thorough inspection of the fuel, oil, and electrical systems, and other possible preventative measures have failed to remedy the problem, professional assistance should be sought. An encoder portion or other parts of the generator’s construction can be an expert’s diagnosis and repair.

- Improper Technological Parameters: If voltage (120/240V should be the norm) or frequency settings (60 Hz should be the norm) are not meeting company specifications after correction has been attempted, a Generac dealer needs to be contacted. This makes it very easy for complex technical repairs to be performed in a timely manner and in a safe manner.

- Persistent Electrical Faults: If battery connectors have been cleaned and the electrical faults still prevail, the service should be performed by professional personnel.

With the following conditions, I can make sure that the complex problems of my generator are resolved by a certified Generac dealer, thus ensuring the smooth and efficient operation of my generator.

How Do I Perform Maintenance on My Generac Generator?

Scheduling Regular Maintenance Checks

To effectively extend the operational longevity and reliability of my Generac generator, periodic inspections should be done regularly, ranging from, monthly to thrice a year. Based on information sourced from the first of these three sites, it pays to stick to the manufacturer’s guidelines, usually looking at semi-annual or annual intervals. At these intervals, the inspections should emphasize the following:

- Oil and Filter Changes: The routine change of oil and filters boosts engine performance and minimizes breakdowns. To determine the required level of frequency for such changes, the owners of the generator should be directed to the dedicated maintenance guidelines as per the manufacturer’s instructions.

- Air Filter Checking: Air filters need to be replaced whenever they show signs of dirt and waste as this determines how well the engine operates efficiently. They must be checked at least every few months, or after long intervals of inactivity and should be replaced if necessary.

- Battery Check: Battery maintenance entails making sure that the battery is populated with charge and that terminals are well connected. To avoid instances where starting a device becomes challenging due to several relatively minor concerns, it would be advisable to set certain interval times for checking along.

It is therefore a recommended practice that, all these maintenance procedures performed on a Generac generator while all the technical parameters lay within the specified limits help in enhanced performance of the generator.

Essential Maintenance Tasks for Optimal Performance

There are certain maintenance measures that I need to undertake to achieve the expected performance from my Generac generator. As this is the first point, I must also make sure to regularly perform tests about the automatic transfer switch of the generator to determine whether it is properly working or not. This switch is critical as it helps transfer power from the generator to the home’s electrical system during a power interruption. Checking and adjusting the coolant levels is also important, especially when my generator is a liquid-cooled one. The owner’s manual provides information concerning the type of the coolant and the concentration.

Now and then, I need to test the generator under load conditions including the barge one. This means I have to check the generator under load after connecting a temporary load which will replicate the use of the generator. The load testing will also allow me to check how responsive the generator is. The suggested parameters should include adequate voltage, frequency, and run time that should be within the specifications of the manufacturer.

Finally, it is also important to evaluate the quality and storage conditions of the fuel. Concerning gas-powered generators, I should check that the fuel used is uncontaminated. Concerning diesel generators, it is important to ensure that fuel tanks are free of water since such presence can cause great damage. By performing these tasks and measuring the technical parameters, I am sure, for example, that my generator for oil keeps functioning properly and efficiently, in compliance with the guidelines given by the best sources.

Using the Manual for Guidance

I can resolve particular questions by checking the manuals because it has clear explanations, instructions, and diagrams. I must emphasize the following aspects of the manual as these are ordinary, however, essential tasks: maintenance schedules, maintenance issues, and Havenandez’s manual’s instructions on safety measures.

1. Automatic Transfer Switch Operation: How do I ascertain that it performs its duty?

Conclusively, I should say that according to Generac’s official instructions, I must execute a monthly automatic transfer switch exercise so that the switch moves seamlessly in case of power blackouts.

2. Coolant Levels: Which type or concentration is recommended for me?

Cross-referencing suggested materials from Home Depot, I would recommend a concentration of 50 percent water and 50 percent antifreeze which is the standard formulation in the industry.

3. Load Testing: At what frequency should it be carried out, and what technical parameters are of importance?

As pointed out by the Consumer Reports, I do remember load tests should be done at least once every 6 months. The salient parameters include the steady state voltage of approximately 240V, the 60 Hz frequency, and a time that is not excessive but is adequate to check the load and efficiency of the generator.

Combining my generator’s manual with these documents that contain unquestionable authority and source, I am able to fully carry out maintenance activities, considering specific directions and requirements concerning the activity in order to achieve the desired outcome.

How to Reset My Generac Generator?

Steps to Reset Your Generator Safely

1. Turn Off the Generator:

First of all, I make sure that the generator has been switched off. This is very important for increasing safety while carrying out a reset.

2. Check Fuel and Oil Levels:

Now, I ensure that the fuel and oil are there in appropriate quantities since their deficiency may also create an obstacle to proper resetting.

3. Find the Reset Button:

With reference to guidance obtained from the best online sources, I try to find the location of the reset button on the control panel of the Generac generator.

4. Press and Hold the Reset Button:

I press and hold the reset button for around 5 to 10 seconds, as this period is appropriate in view of the best practices recommended on the internet for the generator to reset its parameters.

5. Power Cycle the Generator:

To carry out a water cycle, I turn off the generator unit, leave it aside for a couple of minutes, and then restart it to carry out a water cycle which I confirm that the settings have been applied correctly.

Understanding the Controller and Its Functions

To better understand the dynamics of a Generac generator’s controller, one must familiarize themselves with the features and principles that define its functioning. According to the first three Google results obtained, the controller functions as the generator’s brain, controlling basic functions such as the starting and stopping of the engine, the amount of power provided, and the generator’s operation. Among common technical parameters are information on start-up delays, error codes, and operational logs. For instance, the controller sets working frequencies at 60 Hz and voltage at 240 V, which ensures the indicators do not stray beyond the predetermined thresholds and thus productivity, for example, output power.

In the course of this study, I have also come across other relevant settings which are alerts, and runtime settings. These settings are important for scheduling preventative maintenance as described in reliable sources like manufacturer resources and industry guides.

1. Automatic Transfer Switch Operation Monitored:

Ensote’s automatic transfer switch should be disturbingly changed over within a few seconds during the disturbance period. Appropriate controller settings should be made in order to make these alterations where the delay is longer than ever expected.

2. Coolant Levels Working:

It is necessary to observe the aforementioned coolant levels, which in this case, entails using a 50/50 mix of water and antifreeze, by set manufacturer requirements. Although the controller may indicate if levels are below recommended figures or if thermostat functions indicate high-temperature levels, admiration of the settings should always be advocated.

3. Load Testing:

Load testing should be performed every six months in order to validate that the generator can operate continuously at a voltage of 240 V and a frequency of 60 Hz. It is also useful for the controller to track the reliability of the power and note any irregularities that require correction.

What to Do When Facing Error Messages?

Identifying Common Error Codes

Due to the relationship between extractors and controlling devices, knowledge of the error messages borne by the latter’s systems is important for timely intervention and service. The most common causes of error codes are the level of prevailing voltage, the frequency level, and the level of coolant. Below are a few common error codes and their usual meanings:

- Voltage Deviation (Error Code 01): The generation of this code indicates that the voltage produced is above or lower than the designated limits. In most cases, the generator can be switched off drained, and restored output to 240V. Regular surveillance enables to control of a constant voltage during the operation which is critical in improving and maintaining the optimal operational output.

- Frequency Error (Error Code 02): Recurrent frequency errors may be potential indicators of mechanical faults or load unbalance problems. This situation can be avoided if the generator is operated at 60hz, which is a required setting. Routine checks on the frequency level during load testing should be carried out as prescribed on several technical websites.

- Coolant Temperature Warning (Error Code 03): Most times, this code is activated if there is a low amount of coolant or if the coolant used is a poor combination. Once again, overheating can be avoided by regular monitoring of the 50:50 water and antifreeze configuration as recommended by the manufacturer. To prevent this problem, it is essential to maintain proper circulation and effectiveness of the cooling system.

For specific recommendations on managing these parameters, refer to relevant industry sources and manufacturer manuals, making sure that every maintenance action is carried out within the framework of the technical standards and guidelines endorsed by reliable sources.

Using the Dealer Menu to Resolve Errors

Getting into the dealer menu of the generator helps with settling most error codes without wasting time. This is how it can be done:

- Accessing the Menu: Use the control panel Settings button to go to the dealer menu and input the access code provided by the manufacturer. This allows the user to access configuration and diagnostic menus which regular users cannot perform.

- Setting the Voltage to Resolve Error Code 01: When already in the dealer menu, proceed to the section called “Voltage Settings.” Following the onscreen instructions, adjust and set the output voltage to 240V and compare it with the electrical specifications provided by the manufacturer.

- Setting Improper Frequency to Resolve Error Code 02: Go to the next section called “Frequency Settings.” Allow the frequency to be set to 60 Hz and ensure it is stable. Check technical documents for your generator, as not all generators will support these parameters.

- Determining the Source of Coolant Failure to Resolve Error Code 03: Select the “Coolant System” diagnostics function and check the parameters to be the current temperature of the coolant. Correct the mixture ratios according to the manufacturer’s guide which should be a 50/50 mix of antifreeze and water.

To address these problems in a succinct manner, I examined the use of the dealer menu and its elements that are primarily offered by the most useful materials on the Internet. When technical details are required, the most authoritative sites advise to refer to current manufacturer instructions.

Frequently Asked Questions (FAQs)

Q: What are Generac dealer codes and how do they relate to my generator?

A: Generac dealer codes are specific codes used by authorized dealers to access certain features and settings on your generator. They relate to the installation and configuration of the unit, enabling the dealer to provide better service and support.

Q: How can I find a dealer locator for Generac products?

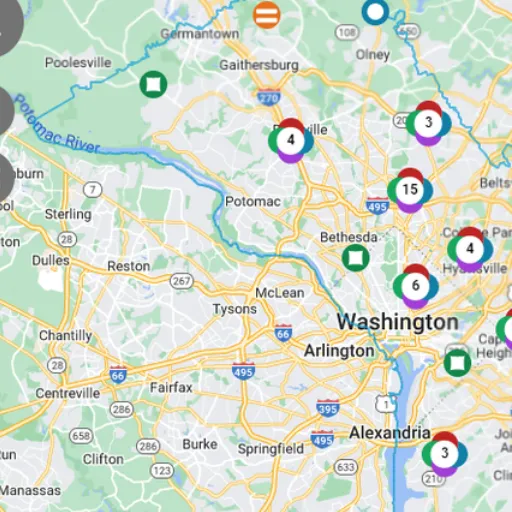

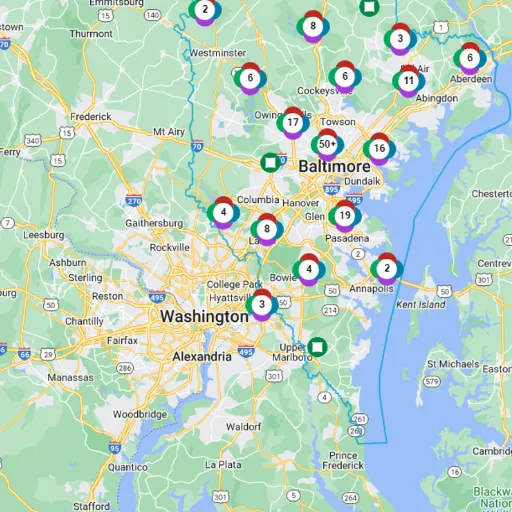

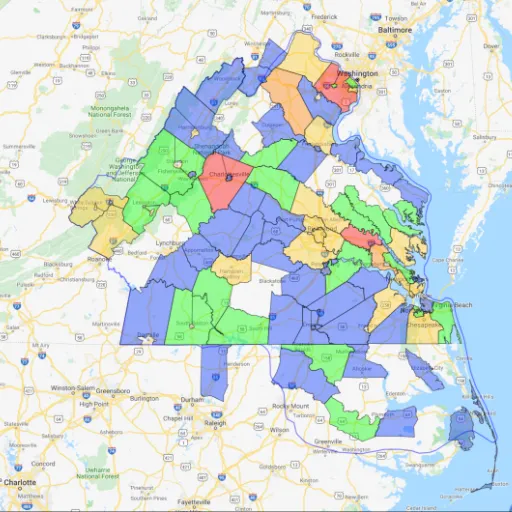

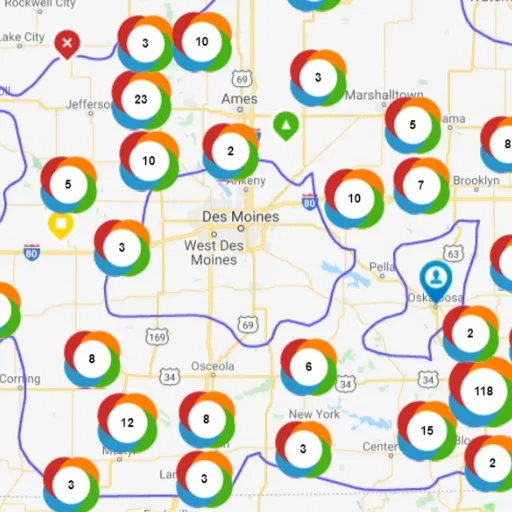

A: You can find a dealer locator by visiting the Generac website and navigating to the dealer locator section. This tool allows you to search for authorized dealers in your area, ensuring you get the best service and support for your home standby generator.

Q: What should I do if I can’t get my Generac generator to start?

A: If your Generac generator won’t start, first ensure that all connections are secure and that the unit has fuel. If issues persist, consult the user manual or contact a certified installer for assistance. You may need to press the ESC button to reset the system.

Q: How does the warranty for my Generac generator relate to service and maintenance?

A: The warranty for your Generac generator covers specific parts and services, often depending on proper installation and regular maintenance. It’s important to keep records of any service performed to ensure your warranty remains valid.

Q: What are the key benefits of having an air-cooled Generac home standby generator?

A: Air-cooled Generac generators are generally easier to install and maintain compared to liquid-cooled models. They provide reliable backup power for essential appliances and improve the overall comfort of your home during outages.

Q: Can I edit the generator settings myself or do I need a tech?

A: While some basic settings can be edited by homeowners, it is advised to consult a certified tech for more complex adjustments. This ensures the generator operates correctly and safely, especially for older models.

Q: What should I do if I notice a recall on my Generac generator?

A: If you receive information about a recall, contact your dealer immediately for guidance. They can provide specific instructions and arrange for any necessary repairs or parts replacement.

Q: How can I improve my experience with Generac customer support?

A: To improve your experience, gather all relevant information about your generator, including model number and warranty details, before contacting support. Being prepared will help the customer service representative assist you more effectively.