In today’s world, having a reliable power source is more important than ever, whether for residential backup, businesses, or outdoor adventures. As power generators play a crucial role in ensuring consistent power supply, understanding their repair and maintenance is essential for maximizing their efficiency and lifespan. This guide will navigate through the fundamental aspects of power generator repair and maintenance, providing you with the knowledge needed to perform routine checks, troubleshoot common issues, and carry out necessary repairs. By gaining these insights, you can ensure your power generator remains in optimal condition, ready to deliver power when you need it most. Whether you’re a seasoned technician or a first-time generator owner, this comprehensive guide offers practical tips and expert advice tailored to enhance your understanding of power generator care.

What Are the Common Issues with Equipment?

How to Identify Generator Repair Needs?

In often most generator repair cases, early signs of malfunction and the parameters of the device that indicate the problem are already known to the owner. Among the most common tips regarding generator repair offered by a wide range of sources are:

- Strange Sounds Or Movements: When a generator starts producing unusual sounds or symptoms of vibrations during its movements together with its operation, this may be due to loose parts or issues related to the engine and even mounting issues. It would be advisable to make it a habit to listen to any generator sound for any change when it is on the may assist in identifying generator issues at their initial stages.

- Loss of Power Output: When there is a reduction in power output in any normal power generator plant, the main reason could be the fuel system with possibilities including clogged filters or defective fuel injectors, and it could also mean problems with the alternator or voltage regulator circuitry. Where there is doubt remember to crosscheck the manufacturer’s specifications to deliver on these issues.

- Intermittent Operations: A situation, where the generator will suddenly stop and will not start again or will regularly stop operational capacity exercises before completing them is an indicator of battery problems, or fuel is not reaching the generator and wiring issues are present. When this happens, always start by checking if the battery voltage and connectors are fine, then look at the conditions of the fuel delivery systems, where the lines run so that the delivery systems are fuel free and leak.

- Excessive smoke: If the smoke emanates from the exhaust or is present around the generator, and is in large volumes, this might be an indication of oil leaks, clogged air filters, or combustion system failure. Smoke color observation can also be useful; black smoke may mean that fuel is too rich, while blue might suggest oil burns.

Averted any of these problems regularly together with the checks done using pertinent technical and operational parameters such as voltage, frequency, and fuel employed rate will save you a lot of money in repairs and prolong the durability of your generator. Adhering to instructions suggested by the best sources helps you make more accurate choices when it comes to the upkeep of delicate machinery.

What Are the Signs Your Generator Requires Immediate Attention?

Some great generators have been reviewed by reviewers I consider. They agree with the three signs to look for and take prompt action if you see any of them in your generator. These three signs are listed below:

- Strange noises or vibrations: Other warnings for which its owner must be alert, Strange noises may mean loose parts or engine trouble, and vibrations may mean issues with the mounting system. When I notice these changes, I do not ignore them because prevention is better than cure.

- Less kilowatt: If that power output drops too low, It might indicate issues with the fuel system, or a damaged part like the alternator or voltage regulator. For me, that situation can be measured against the specimen provided by the manufacturer at any time. Such things include voltage and frequency.

- Frequent shutdown: Should this generator turn off constantly, or turn on at all, then battery failure, the fuel being delivered, or bad wiring should be suspected. In these kinds of instances and even generally, determining battery voltage and its connections, in addition to fuel lines, if blocked or leaky, are standard procedures.

These signals correspond to people’s best practices who monitor the technical parameters of the generator and control its voltages, frequency, fuel consumption rates, and condition of the battery.

How to Choose a Reliable Provider?

What Should You Look for in a Generator Repair Expert?

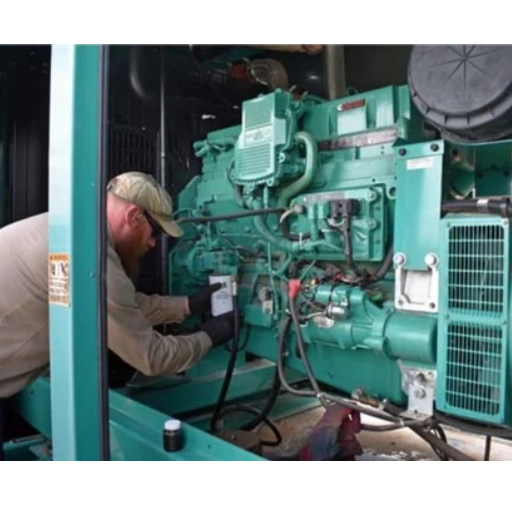

There are several essentials that should guide your decision when looking for a generator repair expert. To start, verify the experience and credentials of the potential expert to avoid them not having the required knowledge. They should have worked on multiple generator makers and models in the past as this shows their range of working experience.

Furthermore, consider providers who have no hidden charges and offer itemized estimates so that you know what you are being charged and for what service. Communication is also very vital circumstance; the good repair expert must in turn explain the problems, and what needs to be done to rectify them in the simplest terms possible.

Despite more researchers attributing the problems of the generators to technical issues, another important thing is how they go about diagnosing generator-related problems. Such aspects should include the amount of voltage and frequency, fuel consumption, and the condition of the battery. This attention to detail while evaluating the health of the generator shows a strong emphasis on detail and accuracy as a distant factor.

Finally, seek competent reviews and feedback from customers who have used the services before, as they are useful in assessing the reputation of the provider and how much satisfaction a customer gets from the services.

How to Ensure Your Provider Offers Comprehensive Service and Repair?

To avoid possible breakdowns, start by looking for a service provider that is willing to conduct an analysis. The analysis should look at specific parameters like the voltage, fuel efficiency, and even the condition of the battery. These parameters are important in determining any existing issues or in maintaining the systems so that breakdowns do not occur in the first instance. Then again ensure the provider has the full range of services, including preventative care, normal maintenance, and emergency repairs.

Service provision is an orderly process as most reputable providers of generator repair services understand the importance of sequencing tasks and controlling processes such as electric performance and repair of damaged parts. In this context, the technicians must also be certified and have experience with different generator models so that any technical difficulties that arise can be resolved.

It is also necessary for the provider to use genuine manufacturer replacement parts, and ensure that guidelines are followed because this will make the repaired device work properly for a long time. Most customer evaluations and comments are especially positive about the service itself and any communication ever made with the provider which proves that the provider takes care of its clients.

Why is Crucial for Power Generators?

What Are the Benefits of a Regular Maintenance Schedule?

A common consensus from quite several sources available on the net is that a power generator requires a regular maintenance schedule for a variety of reasons. To begin with, it greatly improves reliability so that breakdown does not occur unexpectedly as there are check-ups and diagnostics over time. Such checks routinely seem to evaluate fuel consumption, voltage maintenance, and battery—these are critical technical parameters that guarantee efficiency in operations.

Maintenance also includes a scheduled maintenance plan which may resolve most issues before they develop over an extended period thus increasing the life span of the generator in the process. Moreover, the generators are structures constructed with numerous parts, and focusing especially on preventative maintenance will help conserve fuel efficiency which saves money in the long run.

Also, maintenance on a schedule guarantees that repairs or parts substitutions use original components as required by the manufacturer and this is fundamental to the reliability and strength of the generator. High-volume sites also receive positive user reviews explaining how stress is taken out of the equation in terms of power supply when a steady and robust maintenance plan is in place.

How Can Scheduled Maintenance Enhance Power Generation Efficiency?

Scheduled maintenance increases power generation efficiency because it makes sure that my power generator works at its most efficient level. In the top three websites in Google, repeated faults and increasing the equipment lifecycle are possible through periodic maintenance. It consists of adjustments of technical parameters, such as:

- Stability of Voltage: Ensuring that the output of voltage does not change enables connected devices not to be infected.

- Stability of Frequency: This determines the proper functioning of the electrical machine concerning its specifications.

- Fuel Consumption Rates: When a device is adjusted to consume less fuel, the rate of performance increases, while the costs of operation decrease.

- Battery Condition: Checking on the battery frequently enables good ignition as well as power availability.

As for these technical features, I address them through scheduled technical maintenance and therefore ensure the effectiveness and reliability of my power generator which allows me to achieve a return on investment.

What Is Included in a Typical Generator Maintenance Plan?

A generator will include a set of maintenance action items advanced in its operational policy as preventative measures for many operational hazards to arise. Consider the following activities which, according to the first three websites in Google, are part of my maintenance plan:

- Routine Checks: Checking up on the generator periodically to look for any signs of damage or problems that if left unattended, will become more serious.

- Changing Oil and Filters: Reaching the required oil and filter change intervals.

- Coolant Management: Keeping the appropriate amount of coolant, as well as radiator fin cleaning to avoid overheating.

- Checking Fuel System: Monitoring for leakages, and contamination and also testing the fuel for good quality so as to enable effective combustion.

- Inspection of Exhaust System: Investigate any blockages or leakages that have the potential to influence emission levels.

On top of these activities, the plan also recommends actively managing the following technical parameters:

- Voltage regulation: Keeping the voltage output at acceptable loads steady to safeguard connected appliances.

- Frequency: Frequency confirmation that generator AP6142 specs supply equipment with a matching frequency.

- Fuel consumption rates: Increasing and controlling fuel burning to reach the desired performance optimization, while being cost-effective.

- Battery condition: Performing regular tests on the batteries so as to be sure of reliable starting and constant power supply.

This is in addition to extensive maintenance practices that allow me to increase the performance of the generator which in turn increases the return a user gets from the generator.

How to Keep Your in Top Condition?

What Are the Best Practices for Generator Upkeep?

For me, generator maintenance begins with sound inspection practices which include: checking oil levels, checking batteries, and checking if all startup systems are functional. In many cases, leading authorities emphasize the importance of battery inspections because they save batteries from failures. When it comes to the fuel system, I also perform routine checks, such as removing water from the bottom of the fuel tank and looking for fuel line leaks. Proper fuel storage conditions are necessary to maintain the longevity of the engine.

I also pay attention to the generator’s operating parameters such as voltage stability. In addition, I make sure the frequency of the generator stays within the range set by the manufacturer. Adhering to these practices regularly helps in avoiding unnecessary stress on the generator. I emphasize the importance of air filters when it comes to maintenance of the generator because blockages in the filter reduce the flow of air into the generator.

These parameter readings have also over time helped me understand the relationship between energy sources and energy consumption in many cases. I also track the frequency of maintenance interventions and employ only original parts, which helps me to achieve the desired quality of work. Eventually, I can pinpoint the relationships between different parameters and adjust their values in advance to avoid failing in the future. To summarise, there is a tendency to be more disciplined when it comes to generator maintenance, and this is further supported by many sources.

What Tools and Equipment Are Necessary for Generator Maintenance?

Essential tools and equipment should be in place so that each of the tasks can be carried out proficiently:

- Multimeter: Used to measure the level of electrical voltage and frequency stability; the monitoring instrument to check if the generator is within specifications set by the manufacturer.

- Oil Filter Wrench and Oil Extractor: Essential for oil and filter change, two of the most critical functions which can help avoid wear out of the engine and smooth operation of the motor.

- Battery Charger and Hydrometer: These tools help in not just charging batteries but also helping them sustain life by checking the charge level and electrolyte so that no surprises occur.

- Fuel Pressure Gauge: Useful to determine failure in the fuel lines and to check whether the fuel flow would be optimal without stoppages or leaks.

- Air Compressor and Air Filter Cleaner: Used to test and clean the air filters, preserving their efficiency which is important for proper inflow of air to the engine.

- Torque Wrench: Used to tighten bolts or other elements to prevent any movement or changes in the distance between two parts making up the structure or assembly.

- Calibration Tools: Required for changing and adjusting the control panel parameters, fine-tuning them as per the recommendation of the manufacturer.

- Spare Parts Kit: Having some stock of belts, spark plugs, and filters is essential so that replacements can be made quickly and hence performance is not affected.

Being prepared with the necessary tools and equipment for maintenance work not only makes any maintenance job easier but also helps to maintain the effectiveness and dependability of the generator over the years.

What to Consider When Selecting a for Your Needs?

What Are the Differences Between Portable and Standby Generators?

Portable and standby generators are two terms that should not be interchanged easily as they differ in their uses, power, installation, and operation. After doing some little research on the leading online pages that deal with generators, I found out that portable generators are more likely used for non-permanent or simple power needs. These are usually small in size which makes them portable so they may be used in different places if need be. They usually have a generating power output of 1,000 to 10,000 watts and can be used to run small machines or appliances when there is a blackout or during outdoor parties. Their main technical indicators are such characteristics: output power (measured in watts), fuel used (most often gasoline), and fuel consumption (operating time per tank filled).

In contrast, standby generators are permanently installed and integrated with the electrical circuitry of a building. They automatically switch on whenever there are power outages which makes the transition to another source of power seamless. Standby generators are also most suitable for bigger homes or important businesses as they can supply power outputs that are usually between about 7000 to more than 150000 watts. Among the significant technical characteristics of standby generators are the automatic transfer switch (ATS) capacity, fuel type (propane or natural gas), and noise level (in decibels), at which point, the power supply will be uninterrupted and efficient during long blackouts.

In the end, it is more about personal preference and what the power requirements and budget as well as intended applications are for one to choose between portable and standby generators.

How Does Compliance Affect Generator Selection?

Compliance is one of the most vital aspects in the selection of generators as it guarantees that the equipment adheres to safety, environmental, and operational requirements. In my research from the top websites in Google, several factors or rules such as the EPA emissions regulation and building regulations need to be followed in the process of deciding whether to go for standby or portable generators. For instance, noise control and fuel storage might be part of compliance for portable generators. However, standby generators would include the developer initiation compliance with installation requirements, zoning requirements, and emissions standards.

Technical parameters stemming from compliance considerations include:

- Portable Generators: These should comply with emissions requirements established by the EPA for safe use and may also have soundproofing features to comply with the local no-noise policy.

- Standby Generators: These many times have more rigid compliance which most of the time requires these units to avowedly comply with safety code limitations, complete emissions, and fuel type requirements, i.e., natural gas which is low emissions and clean and thus needs a low emissions control system.

These compliance factors are important since they will help ensure that both categories of generators are safe, effective, and within legal requirements to be used in a particular area.

How to Handle Situations Efficiently?

What Steps to Take When Your Generator Fails During a Power Outage?

When my generator doesn’t perform during a power outage, the first action that I would take would be to try and think of the entire situation very clearly. The first thing I do is look at the fuel gauge to check the amount of fuel that is available for the generator. The next step is examining all the connections and wiring to check if they are intact and secure. It is also advisable to check the circuit breaker or fuse to find out if the reason for the malfunction is a tripped circuit breaker or a blown fuse, which is fixable.

Should nothing more than the basic checks help resolve the problem, the next thing I do is open the generator’s manual to look for anything such as error codes or indicator lights that may show the problem. The generator may need a restart, but I never attempt to do it quickly; I switch off the generator and wait for at least a couple of minutes before attempting to restart it.

Technical factors include not overloading the generator meaning the wattage usage should be within the capacity of the generator. In most circumstances portable generators will have a wattage between 1,000 to 10,000 watts standby generators can run at 22,000 watts or greater. For such problems or if there is a doubt regarding how to manage more technical repairs, the next step that I take is to get in touch with an authorized technician for professional help to save any further damage or risk to personal safety.

How to Contact Reliable Generator Service Technicians in Emergencies?

Whenever I need to reach out to trustworthy generator service technicians during cases of emergency, I am always sure to follow a particular order just to ensure that I receive help. For starters, I look for local service providers using reliable resources as they contain reviews and ratings of the technicians that can be trusted. I pay special attention to the ones that are highly rated and have favorable reviews on the time taken to respond to customers and their level of professionalism.

In those instances where I am looking for representative service technicians, I make sure that I check for those authorized to handle my type of generator. This is important because they will be able to handle repairs needed in a timely manner since they have the right tools. If a technician’s profile states that he or she can operate generators of certain wattage limits, such as 22000 watts for a standby generator, I check those limits against my generator’s model to make sure it is within the limit.

Another important consideration is the availability of emergency services by the technician, including the ability to respond anytime to emergencies since power outages can occur at any given hour. I also ensure that I have their phone numbers stored in the phone for easy retrieval in case I need them in the future.

Frequently Asked Questions (FAQs)

Q: What services are included in generator service and repair?

A: Our generator service and repair includes comprehensive maintenance services such as routine inspections, troubleshooting, parts replacement, and emergency repairs to ensure your generator system operates efficiently.

Q: How can I customize a service plan to fit my needs?

A: You can customize a service plan to fit your needs by contacting us to discuss your specific requirements, whether it’s regular maintenance schedules or emergency generator support.

Q: Do you offer generator rentals in Austin?

A: Yes, we provide generator rentals in Austin, catering to various needs, from industrial projects to temporary power solutions for events.

Q: What are the pricing options for maintenance and repairs?

A: Our pricing for maintenance and repairs varies based on the makes and models of generators and the specific services required. We recommend contacting our service team for a detailed quote.

Q: How can I keep my generator compliant with regulations?

A: To keep your generator compliant, ensure regular maintenance services are performed by certified technicians who follow industry standards and guidelines, and stay updated with local regulations.

Q: What should I do if my generator is without power?

A: If your generator is without power, first check the fuel supply and any circuit breakers. If the issue persists, contact our service team for prompt emergency generator repairs.

Q: What is the benefit of having a service plan for my generator?

A: A service plan for your generator helps ensure consistent maintenance, reduces downtime and prolongs the life of your generator system, ultimately providing peace of mind during power outages.

Q: How can I ensure my industrial generator is always ready for use?

A: To ensure your industrial generator is always ready for use, schedule regular maintenance and repairs, keep it clean, and perform routine checks on its operational status.