Power disturbances in the current business world can pose hazards that disrupt production and lead to losses. A commercial standby generator is essential for business operations without interruptions, even when the electricity supply is cut off. In this article, we shall look into the crucial features and the chronological order needed to set up the commercial backup generator. We shall look at the advantages of having a source of standby power, how to select the most appropriate generator for you, the target audience of this guide, and some general principles of installation that will help you avoid common mistakes. That purpose will be accomplished by explaining in detail why backup power plans are vital for your business operations.

What is a Commercial Backup Generator?

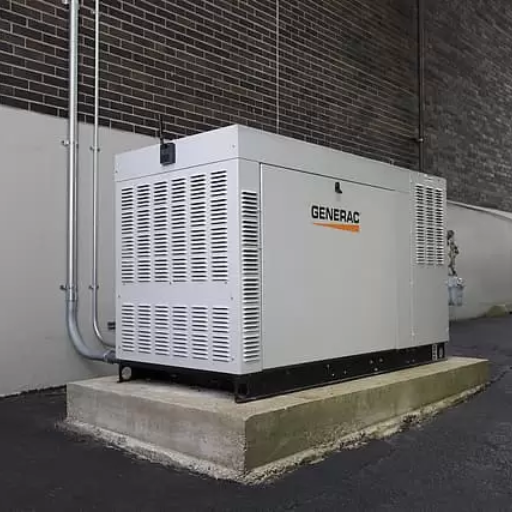

Image source: https://www.csmechanical.co/

A commercial backup generator is a consistent electric power system meant to provide electricity to a business in case the central power system fails. Unlike residential generators, commercial backup generators are constructed obeying the rule of large structures able to produce or support the entire operation of a building or facility along with essential systems and machines. Their usage is done to back up the power supply to a specific business in a way that doesn’t stall the company when there’s a blackout. Depending on the exception of some generators, most use diesel fuel or natural gas. They come in different shapes and sizes to fit the individual business needs. The risks of electrical supply fluctuation that might affect the business’s functionality and sales are averted using commercial backup generators as they provide backup power.

How does a commercial generator work?

We shall start by defining a commercial generator and how it works. Therefore, a commercial generator is a device that generates electricity as a backup source during electricity outages. Power loss is detected by the generator and the automatic transfer switch (ATS) switch on the generator. This means that this switch removes the building from the grid and loads the electrical load on the generator. Usually, the generator is a diesel or natural gas engine, running in a few seconds and supplying electric power. The system works so that the generator gives way to the main supply as soon as it comes back on. The ATS recognizes average power and switches back in a few minutes, after which the generator runs to cool and can be turned off. It is an automated process that prevents businesses from being paralyzed on essential activities with minimal effort.

What types of generators are available for businesses?

While studying different kinds of generators for commercial use, I realized that so many choices are available for various purposes. The leading types are standby generators, portable generators, and inverter generators. These devices are permanently fixated outside a facility and are the most potent regarding standby generators. They are suitable for large organizations that require power without interruptions. They switch on automatically whenever disruptions occur and act as a backup. On the flip side, portable generators are more versatile since they can be taken to different places when needed. Smaller entities in need of power for short durations use these. On the other hand, inverter generators have less output power, but they are efficient and less noisy so that they can be used in places with restricted noise levels. They have their purposes; thus, business operational choices on power requirements avail themselves.

Why are standby generators essential for commercial buildings?

Standby generators exist in commercial buildings to guarantee that relevant systems and processes are in place even during an outage. Such power sources can detect outages, switch on at once, and save on revenue loss due to outages. Besides, those particular details are pertinent while looking out for standby generators: quantity of kilowatts because it should cater to the building needs, method of fuel supply including diesel, natural gas, or propane, and transfer switch for switching from mane electrical supply to the generator. Other parameters include maximum running time and preventive maintenance of parts, both being critical in long-term operation reliability.

Why Should You Install a Backup Generator for Your Business?

Getting a standby generator for your business is advantageous since it allows it to remain functioning in case of an unforeseen power blackout. Such facilities offer efficient backup electricity supply, thus, no interruptions to the functioning of vital systems and equipment. During power disturbances, backup generators work to avoid unnecessary financial implications through operation downtime and ensure sensitive technologies such as computers and servers remain operational. Furthermore, in the presence of such a generator, there is less anxiety about the events of a power failure, which puts everything in the business in a state of paralysis since there are few interruptions in productivity and service delivery.

What are the benefits of having a backup power solution?

In the modern world, backup power solutions are becoming increasingly crucial for both households and enterprises due to the many advantages that accompany their use. One of the main advantages is employees’ protection from the loss of income since operations are continued regardless of the storm intensity or grid failure. Backup power systems also prevent data losses and equipment damage that are expensive to recover by providing temporary power to facilities that require it. They enhance safety and security by giving light and security systems in case of a power outage. Furthermore, a trustworthy backup power solution can increase customer confidence and satisfaction by showing that the service provider is well-prepared and can remain in business without interruptions. Last but not least, backup systems can facilitate flexibility and options in fuel types used, which promotes a greener option depending on the particular requirements and desires.

How can a diesel generator provide reliable power during outages?

Upon pursuing the capabilities and benefits of diesel generators, I noted several aspects. To begin discussing the findings, it must be noted that diesel generators efficiently power critical facilities in cases of power failure. Due to their powerful engines designed for heavy-duty use, these generators can run for days on end without stopping. Their start-up time is also very short, and therefore, power disruption is for a minimal duration. Moreover, among other fuels, diesel can be stored and dealt with fairly quickly, making it useful in case of emergency. The fact the diesel-generating sets are robust and can withstand harsh working conditions for a long time is also alluring. Provided they are serviced regularly, there are absolute worries in the event of a blackout, they will function normally.

What risks do businesses face without commercial backup generators?

When I weigh the possible dangers businesses face without commercial backup generators, several remarkable aspects are brought to my mind. Thus, companies would incur severe interruptions during power cuts, affecting revenue and customer satisfaction without these systems. There is a possibility of loss or damage of valuable equipment and critical data that can be very costly to reclaim. Also, essential services such as security systems and communication networks may depend on a power resource that may be unavailable, making the business more exposed. All in all, not having a commercial backup generator makes the company liable to challenges that may limit the scope of its ability to bounce back within the minimal time frame.

What Are the Requirements for Commercial Generator Installation?

Several steps should be followed while installing a commercial generator. First, necessary permits must be obtained, and all local codes and regulations must be observed. This makes it essential to work out something with the local government. The generator should be placed on even and firm ground, such as a concrete slab, to avoid problems during operation. There must be sufficient distance to allow for the movement of people and the heat generated and to spare the area from any possible ignition sources. Primarily, a qualified person should provide the electric and fuel supply. In addition, an automatic transfer switch (ATS) is usually required to be installed to integrate the generator with existing electrical systems quickly. Improper installation negates the gains from generator use in a business setup as increased output without enhanced risk of accidents.

What permits are needed for generator installation?

Although there may be variations concerning the specific permits required for the installation of a generator depending on the location, there are generally two specific permits that are always needed: electrical and mechanical or fuel gas permits. It is essential to possess an electrical license to ensure compliance with local electrical codes regarding the generator’s wiring and its interfacing with the existing electrical systems. A mechanical or fuel gas permit is also required if the generator is fueled using natural gas or propane to ensure the fuel delivery system is installed correctly and safely. It is also sensible to look for any zoning regulations since generators can be installed in areas where they are not supposed to be due to the generation of excessive noise or emissions. It is advisable to seek clarification on all relevant permits if there is a need to avoid legal issues by seeking the assistance of local authorities or a professional installer.

How do you determine the generator size for your business?

The first step in deciding the appropriate generator size for my business is calculating the total wattage of all the equipment and appliances needed to function during a blackout. This comprises itemizing such items and their power utilization details, which are usually located at a power marking or a manual around the device. Next, I perform some arithmetic operations where I sum up these wattages and consider some appliances’ starting or inrush amperes, which can cause the power demand to shoot up for a short period. To make a better estimate, I also consider any expected expansion or outlays for other equipment that may raise my power requirements. This exercise can be made easier thanks to the Internet, which can give more specific information depending on business size and type of enterprise. Also, talking to a specialist will probably help me select a generator that suits my present situation and will be needed in all possible operational scenarios, making it practical and economical.

What is the role of a transfer switch in generator systems?

Within generator systems, the transfer switch allows for the safe and efficient changeover of power sources from the electrical grid and back to the generator. In my case, a transfer switch helps eliminate back-feeding, which happens when the electricity supplied to the utility lines flows back into those lines, posing a threat to utility crews. It also helps to protect the lines in an outage by momentarily isolating the premises from the utility line and connecting the generator. This means that when I turn on my generator, power will automatically be sent to the vital appliances and systems in the house without having to lift a finger from the typical ‘switch-on’ position, which is an advantage, especially at unexpected power loss moments. With a transfer switch, I still observe all the electrical codes and even improve the safety of my electrical system.

How to Choose the Right Commercial Generator for Your Needs?

Electrical power generation is one of the further sights on the list of considerations visitors consider when setting up their commercial centers. Primarily, stress starts with the requirement of watts to run specific power-sustaining equipment. This also includes knowing both the starting and running wattages, as some devices need more power to work once switched on. Secondly, you have to determine the fuel that is right for your business, whether it is diesel, propane or natural gas, all these come with different pros and cons. Take into account the geographical positioning of the generator and its surroundings, if it does not break any laws and codes, if there is enough room for check, very few too dull, rational-minded, and mechanistically experts V-shaped front walls in few places have flown a tiny hinge engine compartment ventilation. It is also essential to these criteria to add the degree of noise, remote monitoring, and maintenance actions applied to the generator, as well as some others that could extend operating effectiveness. Last but not least, buying a generator requires some foresight so that the model used will adapt to changes in operations over time due to internal or external conditions 685. Emphasizing these factors will assist you in making a prudent decision and maintaining a seamless supply of electricity to your operations.

What factors should you consider when selecting a generator?

The generator’s selection process begins with assessing the required power, ensuring that the generator’s rating capacity can support both the peak and continuous loads of critical equipment. Consider the available fuel types: diesel, natural gas, or propane, as well as the cost, availability, and environmental concerns. Seek everything regarding dependability and durability, but more importantly, look for generators with a good reputation and heavy construction for durability. Consideration will be given to noise, especially in an urban setting, by selecting generators with noise acoustic features where necessary. Finally, all related aspects, such as installation, maintenance, availability of parts, and warranty, should be evaluated to promote effectiveness over time. Helpful tips may be sourced from reputable sources and specialists concerning a particular case to ensure a generator that meets the current necessities and project future needs is selected.

Should you choose a natural gas or diesel generator?

Before choosing between a natural gas or diesel generator, from my research, I have learned that natural gas generators are generally quieter, have lower emissions, and can guarantee fuel supply consistency, which is helpful, particularly in cities. Of course, they may involve more auxiliary development for a higher upfront installation cost. On the other hand, diesel generators are known for their reliability with fuel consumption and longevity, providing useable power in extended outages. They tend to be cheaper over time due to saving on much fuel, although fuel storage in diesel may be a problem. Therefore, I will be trying to reach a compromise, as is often the case, based on various factors, such as required power output, price of the equipment, and perspectives.

Where can you find commercial generators for sale?

In the case of commercial generators, one can quickly locate them online via certain respectable vendors and marketplaces. To start, a site like Generac or Cummins offers customers various quality commercial generators since they buy directly from manufacturers that provide security and technical assistance. Their portals also describe the different products, ratings, reviews, and guides to help select the suitable model. In addition, internet shops like Amazon and Home Depot provide a range of generators from different manufacturers, thus allowing customers to compare prices and reviews other customers provide regarding the products. Finally, websites for the industrial sector, such as Cat Electric Power, or industrial equipment, such as Power Systems, offer business consultations and sales for businesses with specific needs. Such resources ensure that a wise purchase is made in line with the customer’s operational needs.

What is the Process of Installing a Commercial Generator?

Installing a commercial generator is very careful and must be performed in a few steps, every one of which is critical for the proper arrangement and functioning of the generator. The first step includes a site visit to assess and select an appropriate position for the generator, including details like distance from the Building, ventilation needs, and access for maintenance, which must be accessible. Equipment for the building is recommended afterward, and a load analysis may be carried out to confirm that the generator’s capacity will be enough for the electricity required by that facility. Once the site is ready and the generator has been selected, the next thing to do is prepare for the installation of the generator, namely making a leveled base or a concrete pad that will hold the unit. After mounting the generator, Apple is then connected to the plug board of a building. This usually requires the installation of a transfer switch for switching over after the utility power is restored. The final step is testing and commissioning, which is essential to ascertain the operation of the generator under varied loads so that when the need arises, the set can be ready for action. The process ensures that local codes and manufacturer requirements are followed for safety.

What steps are involved in standby generator installation?

The primary thing I do is always find an adequately well-ventilated site outside the building for the standby generator set installation. After that, I ensure that a correct load analysis is done so that the power needed for my facility is appropriate for the generator chosen. After that, I construct a level and solid concrete pad to hold the generator’s weight. After this, I prepare the generator installation: hooks are installed for lifting and transporting the system, and connections are provided for joining the system to the house. Next, I carry out all the necessary installations and try to connect the unit to the house’s electrical system, usually requiring the installation of a transfer switch to quick switchover from the standard electrical supply to the electrical supply from the unit. Ultimately, I perform systems testing and commissioning to confirm that the system will operate and respond to power changes by logging in to the diesel generator’s controls. During all these procedures, I ensure that all laws of the locality and instructions by the manufacturer are observed, enhancing security and productivity.

How can you ensure the proper installation of a backup generator?

There are important considerations to keep in mind for the proper placement of a backup generator. Start by choosing the optimal location with good ventilation and observing planning requirements that prevent problems of overheating and exhaustion. A certified electrician or generator professional should analyze facility power requirements to ensure the generator is sized correctly for your building. A robust concrete slab is an important man’s structure in terms of strengthening the base for the placement of the generator. Install a transfer switch to connect the generator to the power system and enable fast power changeover after a power outage. Adequate and rigorous tests and commissioning works must be undertaken concerning several variables to demonstrate design correctness under these conditions. Respect to local codes and those according to the guides of the generator manufacturer must be observed for the practical function of the equipment and safety. Even after the setup, there should be an emphasis on routine service, inspection, and maintenance reliefs of the generator system.

What inspections are required post-installation?

Specific steps must be undertaken to ensure a backup generator works appropriately after installation. First, the generator needs to be inspected to examine the equipment’s status and ensure that no defects or parts have been worn out. The resulting physical examination should include the fuel system, where all fuel lines ought to be checked for tight and leak-free attachments and tight and insulated electrical connections. A working battery and proper voltage during the starter engagement are ensured by checking the battery leads for any voltage level and examining the battery leads.

A load bank test will evaluate how much power the generator can take on load and whether it will be sufficient for the intended power demand. Ensure that the oil and coolant are at the appropriate levels and that the pointers are in the usual sections for filling up the oil between add and complete on the dipstick or indicating instrument. Obstructions that block the exhaust system must also be cleared out, and the exhaust system must be allowed to function under safe conditions. Last, the transfer switch’s working principle will be checked to assess how quickly and successfully it operates when switching between power from the utility and the uses of electricity generated by the standby power system. Each of those inspections ought to conform to the technical parameters of the generators as provided by the manufacturers and local regulations for safety and optimum performance.

How to Maintain Your Commercial Backup Generator?

Taking care of your commercial backup generator is essential if you want it to work well and last long. Follow it with oil changes and checking coolant levels as per the manufacturer specifications, these could be done between 100 to 250 hours’ post operation interval. Do the air filter inspection and cleaning, as failure to do so leads to inefficient airflow and dirt accumulation. If the battery needs to be restored, perform a simple voltage check and clean any corrosion over the terminal connections. The internal parts of the generator must be checked once every year, along with the load check, to ensure that the unit loads and can work when needed. Dust is another enemy of a generator, and removing or avoiding its presence around the unit, even if it means wiping surfaces off, ensures that stuff is not packed tightly against the generator to prevent overheating the engine. Finally, arrange for such maintenance service with an annual scope of work when a qualified technician will perform the repairs and assessments. Following these maintenance measures will increase the availability and effectiveness of your auxiliary generator.

What routine maintenance does a standby generator require?

Specific steps must be followed to guarantee that the standby generator runs efficiently regarding its routine maintenance. Start by checking the level of the engine oil and the oil filter, and after that, replace them per the manufacturer’s recommendations within 200 work hours or a year. Also, observe the coolant since lack of it may lead to overheating, and inspect the air cleaner element for obstructions. In addition, replace the battery if it does not hold a charge, or every two to three years. Check the security and integrity of all electrical connections to ensure no loose wires or signs of corrosion will cause electrical faults later on. Every year, under loads bank testing, you should increase the load on the installed equipment while listening to it for any knocking sounds that could mean other mechanical parts are also affected. Lastly, perform regular system checks. You should have a qualified specialist examine the unit for any hints of problems. According to industry best practices, such measures ensure that your standby generator operates more efficiently and has the desired durability.

How to troubleshoot common issues with commercial generators?

When diagnosing commercial generators, I always begin by checking the fuel supply regarding fuel volume and contamination. Encounters with generator fuel often turn out to be one of the generator trouble points. I will next confirm the oil levels and the oil’s condition because a generator will not function properly when the oil is low or dirty. Should the generator not respond well, I will check out the battery to see whether or not it is topped up and its connections. These checks aim to uphold the recommended procedures by leading companies in the industry field to achieve efficient troubleshooting.

When should you schedule a professional inspection?

Your commercial generator is expected to be inspected by professionals every year. This practice, no doubt, optimizes performance and safety. However, the progression of specific usage patterns and technical specifications may make it necessary to increase the frequency of inspections. Inspections can be carried out every six months for critical running generators or those that sustain constant extensive load usage or work in extreme situations such as high temperatures for extended periods. After inspection, critical technical criteria such as suitable fuel, oil, coolant level, quality, battery condition, and electrical connections should be addressed. In the same way, operational capacity verification has to be performed, including load testing and mechanical inspection, to check for excessive wear. Restorative professional examination and maintenance of the equipment regularly helps avert a likely adverse situation from occurring, hence limiting inactivity and increasing the working condition of the equipment.

References

-

Generator Installation in Commercial Buildings – Worldwide Power Products – Offers a guide on sizing, costs, and placement of standby generators for businesses.

-

Commercial Generator Installation Service – Mr. Electric – Provides professional installation services for commercial generators to meet emergency power needs.

-

What to Know Before Installing Commercial Generators – Woodstock Power – Details the installation process, including site preparation and equipment testing.

Frequently Asked Questions (FAQ)

Q: What are the benefits of installing a commercial backup generator?

A: Installing a commercial backup generator ensures your business remains operational during power outages. It provides critical power to maintain essential systems, minimizes downtime, and protects assets from potential losses.

Q: What are the requirements for backup generator installation?

A: The requirements for installing a backup generator include assessing your power needs, ensuring compliance with local building codes, determining the appropriate size generator, and preparing a suitable location for the unit, including considerations for the fuel tank and ventilation.

Q: How much do installation costs for commercial backup generators typically run?

A: Installation costs for commercial backup generators can vary widely based on the generator’s size, the installation’s complexity, and local labor rates. On average, costs range from several thousand to tens of thousands of dollars.

Q: What type of fuel is commonly used for commercial diesel generators?

A: Commercial diesel generators typically use diesel fuel for its efficiency and long shelf life. Diesel generators are ideal for businesses that require heavy-duty power generation and have higher fuel storage capabilities.

Q: How do I choose the perfect commercial generator for my business?

A: To choose the perfect commercial generator, assess your business’s power requirements, consider the equipment you need to power, and evaluate the generator’s capacity (measured in kW). Consulting with a generator installer can also help tailor the solution to your needs.

Q: What should I consider when considering generator sales for my business?

A: When considering generator sales, evaluate the type of generator (such as industrial or portable generators), check for warranty and service options, and compare prices among different suppliers. Ensuring that the generator meets your required power generation needs is essential.

Q: What maintenance is required for commercial backup generator systems?

A: Commercial backup generator systems require regular service and maintenance, which includes checking fluid levels, inspecting electrical connections, testing the battery, and running the generator periodically to ensure it’s functional. Following a maintenance schedule can help prevent unexpected failures.

Q: Can I install a used generator for my business?

A: Yes, you can install a used generator for your business, but it’s essential to ensure that it meets your power requirements and is in good working condition. Consider having it inspected by a qualified generator installer to verify its reliability and compliance with local codes.

Q: What is the difference between portable and commercial standby generators?

A: A portable generator is designed for temporary use and can quickly move to various locations. In contrast, a commercial standby generator is permanently installed and automatically activated during a power outage to provide continuous power to critical systems.