Installing a standby generator for your home is a significant investment that requires careful consideration of multiple variables. These generators provide a reliable source of power during outages, ensuring your household can function smoothly when the grid goes down. However, the overall cost to install a standby generator is not a fixed figure—it depends on several factors such as the size and capacity of the generator, the type of fuel it uses, the complexity of the installation process, and the specific requirements of your property. This article will break down the key components that contribute to the cost, offering a comprehensive overview to help you make an informed decision when planning for a standby generator installation.

How much does a whole-home generator typically cost?

Average cost range for standby generators

For a whole-home standby generator, the average cost ranges from $5,000 to $15,000. This covers the cost of the equipment and installation. However, this range can vary because of several factors, such as the generator’s power output, fuel source, and installation difficulty.

- Power Output (kW): The range of power output for standby generators is typically between 7 kW and 50 kW. A smaller house may need a generator with 10 kW of power, but larger homes with higher energy needs may require 20 kW or even higher.

- Fuel Type: Natural gas, propane, and diesel are the most common types of fuel. Gasoline is ideal for individuals connected to gas utility lines, while propane and diesel tend to be more convenient in areas located far away from existing gas infrastructure.

- Transfer Switch: An automatic transfer switch (ATS) is highly recommended to ensure smooth power transfer. These switches can vary from 30 Amps to 200 Amps and should be compatible with the electrical panel of your house.

- Installation Complexity: Fuel source distance, wiring needs, and local government permitting can affect the cost of installation.

When you thoroughly measure these factors, you can optimize the generator specifications perfectly to the power requirements of your home.

Cost of portable generators vs. whole-house generators

Evaluating the cost between portable generators and whole-house generators reveals that there are key differences in upfront price, installation, and maintenance costs.

- Portable generators: These small-scaled devices are cheaper than their whole-house counterparts; costs commonly reside between $500 and $2,500 depending on additional features. For instance, a 5,000-watt portable generator, sufficient for powering essential appliances during outages, averages around $700-$1,200. There are minimal installation costs because of the plug-and-play nature that these devices possess; power cords, a manual transfer switch, and compatible power outlets are the only requirements. However, fuel costs should also be taken into account. Because portable generators possess fuel tanks triple the size of normal generators (typically 3-8 gallons), gas and propane have to be purchased more often.

- Whole-house generators: The added features for convenience make the price jump rather large. To provide automatic backup power makes these devices cost between $5,000 and $15,000. A normal generator for a house around 2,000 square feet will need an output of 20 to 22 kilowatts which costs approximately $7,000-$10,000. The high cost is explained by the more complex installation. A whole house generator is wired into the home’s electrical system as well as the fuel source, be it natural gas or propane, making installation costs range from $2000 – $5000. The other expenses related to these types of generators include a maintenance fee of $300-$600 yearly.

However, the overall cost associated with portable generators is way cheaper. Nonetheless, the ease of use, greater volume, and strength of whole-house generators tend to merit the price associated with them due to sustained power consistency. It is, nevertheless, critical to note that both options have unique situations appropriate to their characteristics.

What are the additional expenses when installing a generator?

Transfer switch installation costs

Typically, such a device will cost around five hundred to one thousand and five hundred dollars to put in, but the value depends on how easy the installation is. The basic electrical unit itself is much cheaper as it ranges from two hundred to eight hundred dollars, but one must also consider the extra labor costs needed to set it up. On the contrary, the more advanced unit which starts the generator when it detects a power outage, is much more expensive. The unit and installation will cost between one thousand and two thousand five hundred dollars.

- Amperage: The power rate for the switch needs to be the same as the main electrical panel. The power ratings are usually fifty, one hundred, or two hundred amps. A two hundred amp transfer switch is needed for whole house generators.

- Voltage compatibility: Always check if the switch is compatible with the voltage of the generator. For a residential system, the most common is one hundred twenty to two hundred forty volts.

- Circuit allocation: For the manual type, allocate the circuits that you want the power switch. These types of switches can be used on several circuits but often need different settings for each.

- Installation compliant: Make sure you check installation compliance with the standards and regulations of the National Electrical Code which prohibits installation which poses a safety risk.

By addressing these variables, I can better determine the overall cost and ensure compatibility with my power system for a seamless installation.

Fuel line and electrical work expenses

Costs incurred in construction and electrical works relate mostly to the particulars of the system in question. On the fuel line side of the system, what type of fuel will be used has an impact on the fuel components and installation costs, be it natural gas, propane, or diesel.

- Fuel line diameter: Ensure it simultaneously meets the flow rate requirements for the generator which is usually specified as Cubic Feet per Hour (CFH) or Gallons per Hour (GPH). For instance, a 20kW generator will require a fuel flow rate of approximately 250 CFH for natural gas.

- Pressure ratings: Check that the line pressure is in accord with the generator, i.e. 3.5–7 (in.WC) for natural gas generators.

- Material compliance: Approved materials per the relevant codes, such as ANSI-rated piping are required for gas lines.

Expenses incurred in Electrical works depend on the specifics of the wiring and local code requirements. Technical items about costs include:

- Wire gauge: Sized per the ammeter output. For example, use a minimum of 6 AWG copper wire at standard weather conditions for lower than 50A load.

- Breakers: Sized at 20 percent of the generator output with a typical recommendation of exceeding peak amperage.

- Switch Type: As automatic transfer switches (ATS) ensure proper load transfer, they might be somewhat more expensive, but are always NEC compliant.

I would recommend requesting an on-site evaluation by a licensed technician to accurately calculate installation costs. This process ensures that all technical requirements are considered, and the setup adheres to safety and regulatory standards.

Permits and inspection fees

The different fees arising from permits and inspections depend on the locality, as well as the intricacy of the generator installation. Construction permits are necessary to attest the building meets certain zoning, electrical, and construction standards. The local authorities usually charge between $50 and $500 for solicited permits, although there might be a larger fee in areas with high demand or for particularly intricate installations. However, inspections make sure that the work is done accurately, as well as checking for potential safety hazards.

- Permit costs: These typically account for local government requirements and include building, electrical, and mechanical permits.

- Administrative fees: Payment might include more than one site visit where an authorized inspector checks compliance with NE Power Codes and even the utility company.

- Justification: The installation of equipment and constructions that aim to alter the environment should always undergo proper inspections, which comply with the government’s regulations. Failing to comply could lead to serious problems and costs.

Because of these reasons, it could be easier to contact the local technician or the required office and get the paperwork needed done directly from them to get accurate prices. They can provide assistance with the materials required, the booking procedures, the submission timeframe, as well as any other expenses that could come with the process.

How do I choose the right size generator for my home?

Determining which appliances to power

To decide on the devices that I would like to run on the generator, I first must establish the most important machines and systems that I cannot afford to be offline during an outage. This usually comprises appliances like refrigerators, freezers, HVAC devices, lighting, and even important electronics such as medical and computer devices.

To obtain this information correctly, I start by calculating the wattage requirements for the appliances. For instance,

- Refrigerator Freezer: Approximately 600-800 watts (start up around 1200).

- Air Conditioner Window Unit: ~1000-1500 depending on size.

- Electric Water Heater: ~4500 watts (if required).

- Lighting: ~60 watts per bulb on average for incandescent or 10-15 watts for LED.

- Microwave Oven: ~1000 watts.

- Medical Devices: ~30-90 Watts (e.g. CPAP).

I always ensure that the generator’s capacity in watts running and surge meets or exceeds the combined total of the appliances intended to be powered at one time. For appliances that want surge wattage. I include those values to not overwork the generator. At the end of it all, I make sure to prioritize these appliances based on need and available generator capacity to ensure optimum performance in an outage.

Selecting the appropriate generator capacity

To determine the generator’s appropriate rating, I always begin by noting down the total wattage of all appliances that need to be powered, which also includes running wattage and surge wattage where relevant. For example:

- Refrigerator/Freezer: ~600-800 running watts, ~1200-1600 surge watts.

- Microwave Oven: ~1000 running watts (no significant surges).

- CPAP Machine (or similar medical devices): ~30-90 running watts.

- LED Lighting (4 bulbs): ~30-60 running watts (surge ~10-15 watts per bulb).

Subsequently, I sum this wattage to come up with the total wattage for the appliance’s construction which as a result narrows down the wattage for the generator that is selected. Besides that, I also check the generator’s maximum surge wattage for the selected generator by adding the surge wattage previously established to ensure there is no overload while running the appliances.A s an example, if my running wattage total adds up to 2000 watts and the highest surge wattage is 1600 (for refrigerator/freezer) I would need at least a 2000 running watts generator with a minimum surge capability of 3600 watts. This methodology is very useful for those looking to make sure their generator choices are effective for both their running wattage and surge wattage.

What is the installation process for a home generator?

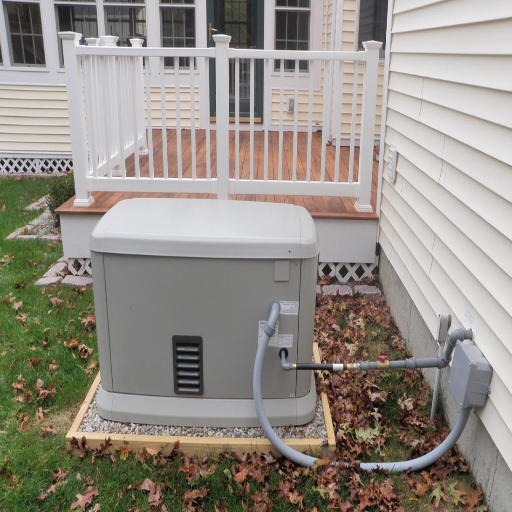

Site preparation and generator placement

Considered to be one of the most important things to do before installing a home generator is to make sure to prepare the site thoroughly and properly. The first step is identifying a suitable location that also meets other local regulations, construction codes, and set instructions by the manufacturer. There should be a minimum gap of 5 ft between the walls or any blanket opening such as windows for the windows to be opened without any hindrance plus ensuring ventilation is adequate alongside minimizing carbon monoxide risk. Furthermore, there should not be debris at the site and the land should be level and stable to avoid vibration damage.

- Clearance Requirements: Maintain five feet safe distance from combustible structures and openings as per the safety standards.

- Foundation: A compacted gravel base or a concrete pad should be used for the generator to make sure there is a strong level foundation that can support the heavy weight of the generator.

- Access for maintenance: 3 feet of space should be left around the generator to make sure servicing is easy and hassle-free.

- Ventilation: To prevent the generator from overheating, it should be placed in an open area where the air can flow freely. Heavily ventilated areas work best for generators.

During the assessment of the site, the competent specialists ought to check essential features such as the proximity to both the fuel source as well as the transfer switch. It is also key to consider proper placement as it optimizes both installation and operational safety while meeting regulations.

Connecting the generator to your home’s electrical system

To hook up the generator with your house’s power wiring, a transfer switch is important so that power is distributed safely and efficiently. A transfer switch stops the undesirable phenomenon of back feeding, generally defined as the flow of power returning into a utility line, which endangers utility employees as well as damages the generator. Depending on the particular case scenario and budget limitations, either a manual or automatic transfer switch is suggested.

- Transfer switch rating: It should equal or be greater than the power supply rating of the generator. Like, if a generator has a 10 kW output then the transfer switch rating should be equal to or greater than 10 kW.

- Generator output voltage: Check the output voltage of the generator 120/240V most commonly used for domestic purposes.

- Amperage capacity: The transfer switch is to be used with the main power panel of the electrical system. In residential cases where the main panel ranges from 100A to 200A, the transfer switch should be rated appropriately.

- Circuit selection: When implementing the transfer switch, vital circuits should be identified first to ensure the most important appliances, HVAC units, as well as HVAC, and lighting systems are operational.

Professional installation is strongly advised to comply with local electrical codes and ensure operational safety. An electrician will perform tasks such as securely wiring the transfer switch to the main circuit breaker panel, grounding the generator properly, and testing the system for functionality and compliance.

Installing an automatic transfer switch

While implementing an automatic transfer switch (ATS), I take responsibility for ensuring that various aspects of operation and safety are correct.

- Rated Power Capacity: I place the ATS at the grade it can support. For most residential installations, this is at least 10KW or above, subject to the output of the generator and the usage by the household.

- Voltage Compatibility: First, I ensure that the amperage of the ATS is equal to or lower than the voltage output of the generator, always below 120/120V- 240V, and last in consideration, the household electrical system.

- Amperage Rating: I derive the complete cumulative voltage capability of the electrical system’s primary board. For example, if the dwelling has a 200A panel, I am going to use a 200A-rated ATS or an ideal ATS.

- Circuit Prioritization: I determine circuit priorities for the ATS covering critical systems such as refrigerators, HVAC systems, or lighting. Doing so serves the purpose of preventing excessive load while allowing power to critical systems during outages.

Such aspects are crucial, and as a matter of principle, I check the local electrical codes and standards before commencing installation. Engaging a qualified electrician to wire the ATS transfer switch is important, as is ensuring it is correctly grounded, and making certain that all connections are tight. After the system is installed, they check and confirm that the transfer functions without any issues and meets the required standards.

How much does generator maintenance cost?

Routine maintenance expenses

The annual costs associated with generator maintenance services depend on their type, capacity, size, and even the service frequency. As a case in point, standard maintenance for small residential generators costs anywhere between $150 and $300 yearly, covering oil and filter changes, battery checks, and other routine inspections. Medium-sized commercial generators, or standby types, need more extensive servicing, so the costs might vary from about $300 to $600 annually.

- Oil Changes: The oil is supposed to be changed after 50-200 hours of operation or as directed by the manufacturer.

- Filters: Air and fuel filters are changed, if necessary, during the annual servicing.

- Batteries: The voltage levels along with terminal connectivity are checked to ascertain that the starting system will be reliable.

- Coolant System: For liquid-cooled generators, coolant levels along with the hoses are checked to avoid overheating.

- Load Testing: To check that the generator produces sufficient watts under an operational load, without high-frequency power variations or other excessive vibrations.

By adhering to these routine maintenance as well as technical requirements, I limit operational and system failure risks during critical use periods while setting optimal generator performance and longevity.

Long-term repair and replacement costs

Long-term repair and replacement costs for generators are highly contingent on the brand, model, and operating conditions. For major components such as the engine or alternator, repair costs can range from $1,000 to $3,000, depending on the extent of damage and labor required. Full component replacement often exceeds these amounts, with alternator replacement costing upwards of $2,500 and engine replacement ranging from $3,000 to $10,000 in severe cases.

- Operating Hours: A generator has a lifetime rated cycle of around 10,000 – 30,000 for high-quality models, surpassing this may require partial replacements or severe overhauls.

- Operating Load: To avoid premature failure, it is best not to run the generator-rated load under 30% for long periods, within the range of 80% to 100% is ideal to lessen the strain on components.

- Maintenance Adherence: To avoid expensive repairs, keeping up with regular servicing can go a long way with appropriate replacements as well.

With the correct implementation of these technical adjustments and constant tracking of particular performance indicators, the operational life span of the generator can be drastically improved while costly repairs and replacements are reduced significantly.

Frequently Asked Questions (FAQs)

Q: What is the average generator cost for a whole home generator?

A: The average cost to install a whole home generator typically ranges from $7,000 to $15,000. However, the total cost can vary significantly depending on factors such as generator size, brand (like Generac), and installation complexity. For larger homes or more powerful systems, costs can exceed $20,000.

Q: What are the main generator cost factors to consider?

A: The main cost factors for installing a home generator include the size of the generator you need, the type of generator (standby vs. portable), brand, fuel type, installation complexity, permits, and possible electrical upgrades. Additionally, the cost of installing a generator transfer switch can add to the overall expense.

Q: How does the size of the generator affect the cost?

A: The size generator you need directly impacts the cost. Larger generators capable of powering your entire home during a power outage will be more expensive than smaller units that only power essential appliances. Generally, you can expect to pay more for generators with higher kilowatt ratings.

Q: What should I expect to pay for generator installation?

A: Generator installation costs typically range from $500 to $3,000, depending on the complexity of the job. This includes labor, materials, and any necessary permits. Keep in mind that some areas may require a professional generator installer, which can affect the cost of installation.

Q: Is it possible to install a home generator without a transfer switch?

A: While it’s technically possible to connect a generator to your house without a transfer switch, it’s not recommended and often illegal. Installing a generator transfer switch is crucial for safety and proper functioning. The cost to install a generator transfer switch usually ranges from $500 to $1,500.

Q: Can I save money with a DIY generator installation?

A: While a DIY installation might seem like a way to reduce costs, it’s generally not recommended. Generator installation involves complex electrical work and local code compliance. Improper installation can be dangerous and may void warranties. It’s best to work with a professional generator installer to ensure safety and proper functioning.

Q: How do I determine what size generator I need for my home?

A: To determine the size generator you need, consider the total wattage of appliances and systems you want to power during an outage. A professional can help you calculate this and recommend an appropriately sized generator. Factors like square footage, number of appliances, and whether you want to power your entire home or just essentials will affect the size and cost of your home generator.