Installing a standby generator can be a significant investment, but it ensures an uninterrupted power supply during outages. For homeowners, this can mean protection against the inconvenience of losing electricity, safeguarding critical appliances, and maintaining daily routines. However, the costs associated with a whole-house generator installation can vary widely depending on several factors, including the size of the generator, the complexity of the installation, and regional labor rates. This guide provides a detailed breakdown of these costs to help you understand the financial considerations involved. Additionally, we will cover the key elements that influence pricing, potential additional expenses, and tips for budgeting effectively for this essential home improvement project. By the end of this article, you will have a comprehensive understanding of what to expect when planning your standby generator installation.

What factors influence the cost of installing a backup generator?

Generator size and capacity

The size of the generator and the amount of power it can produce are of great importance in determining the performance of the generator and the cost of installation. In terms of measuring and determining the generators needed, I take into account the total power primary appliances and systems within the household require during an outage. This output is measured in kilowatts (kW), and the size is typically categorized into three main types:

- Small Generators (7-15 kW): This category is for the small home essentials which primarily comprises lights, refrigerators, and small appliances. These generators are well suited for a household with modest energy needs.

- Medium Generators (16-22 kW): These are designed to handle larger home setups and are capable of powering additional appliances such as HVAC systems and water heaters. These are also a good option for people who are looking for a more comprehensive backup solution.

- Large Generators (23-48 kW and above): This category is for household systems or small commercial setups that are capable of using and converting most if not all, power supplied to them. These units guarantee business operations are seamless.

To ensure the right size, I calculate the wattage of all essential devices and peak power requirements and consider the surge loads from, for example, air conditioning units. Selecting the correct generator capacity not only optimizes performance but also avoids over-investment in larger systems.

Installation complexity and labor costs

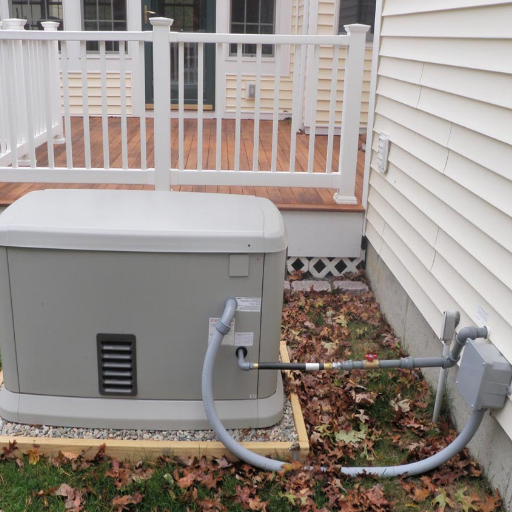

With regards to installation difficulty and the labor costs involved, I focus on first the kind of generator one is looking to install – portable or standby – as this matters a great deal during the installation process. For standby generators, the installation usually involves an electrician to take care of the wiring, a plumber to connect the fuel lines, such as natural gas or propane, as well as an automatic transfer switch. This is quite elaborate and will need detailed scheduling which, depending on the site and permits, could take days. For portable generators, the case is a lot simpler as there is no need for elaborate setups as long as there is a rated power inlet box and transfer switch, and there is a lot less need for professional installation.

- Electrical Load Connection: The amperage ratings of the service wiring of the transfer switch for the standby system should, at a minimum, be equal to the main service panel’s polarity rating (in general, most residential setups are 200 amps).

- Fuel requirements: Configuration Plumbing to connect natural gas 4 to 6 ounces per square inch is standard pressure range or propane 10 to 11 inches of water column pressure.

- Site Preparation: A concrete mount or pad is required to support the standby unit, which usually weighs over 400 lbs for residential models.

- Labor Costs: The cost for labor on the task of installing standby generators could go from $2,000 to $5,000, relative to difficulty, whereas portable systems usually stay under the $1,000 mark for installation support.

These outlined steps ensure compliance with safety standards, minimize installation challenges, and justify the costs associated with each generator type.

What are the additional expenses involved in generator installation?

Transfer switch installation costs

When it comes to transfer switch installation costs, I can confirm that these are influenced by the type of switch and the labor required. A typical manual transfer switch can cost between $200-$800 for the unit itself, while more advanced automatic transfer switches range from $500-$2,000. Installation labor typically adds $300-$1,000 to the total, depending on the complexity of integrating the switch with your electrical system.

- Amperage Rating: Most residential switch expectations are in the range of 100 to 400 amps, and it is necessary to correlate this with the functional servicing panel of the house so that it does not get overloaded.

- Compatibility: The transfer switch has to be compatible with the kilowatt output of the generator so that the demand load can be catered for safety.

- Electrical Code Compliance: Installation must comply with the National Electrical Code – NEC, especially in protection and wiring requirements which is aimed at ensuring safety.

These factors justify the associated costs and provide a seamless, reliable power transfer system during outages.

Fuel line and electrical work expenses

For fuel line and electrical work, I would estimate the scope of work including the specifications system and the fuel line safety to make sure a proper installation is done, to mention some of the examples. In this example, the generator fires on propane; it is important to estimate the type of fuel the generator will be fueled with, be it natural gas, propane, or diesel, and make sure that the line’s maximum allowable working pressure meets the generator’s consumption.

- Supply: Check the pipeline pressure (6-7 inches of water column) of natural gas as it should meet what the generator operates on.

- Propane Size: The tank should be large enough to sustain a domestic propane-powered generator during its operation, so 100 gallons is sufficient for lower power output generators while 250+ gallons is needed for higher output units.

With regards to the electrical system, I would pay attention to the adherence to American NEC directives as to the appropriate size of the wiring, the amount of electricity load, and other significant internal factors such as the cooling system of the sealed enclosure. Examples are as follows:

- Wiring: Use conductors with the requisite rating for the generator output. A 10kW generator at a 120V output supporting a load of 41.7 amps will require a minimum of 8 gauge copper wire, for lengthy distances.

- Circuit Breaker: Check that the generator’s maximum output circuit breaker and the automatic transfer switch cut off the mains at the rated first stage to protect the electrical supply system from overloads.

- Grounding: The generator should be grounded according to NEC Article 250 to prevent electrical hazards.

By addressing these factors diligently, I aim to ensure both cost efficiency and the technical soundness of the installation.

Permits and inspection fees

Here is a breakdown as to how fees concerning permits and inspections can vary. These solely depend on the applicable regulations, the scale of the installation, and the jurisdiction. Typically, obtaining permits for generator installation includes form filing honors that may range from $50 to $500. Moreover, most jurisdictions inspect the site to ensure compliance with safety codes which can be an additional cost of $100 to $300.

Generally, permits delve deeper into the technical side and require site plans, wiring diagrams along load calculations. This is needed to show that the provisions of using NEC Article 445 for grounding and NEC Article 250 are being followed.

- The location of the Generator: This requires a minimum distance/clearance to be kept from other structures. As advised by the manufacturer and local laws, this is usually five feet from openings and other combustible materials.

- Electrical Components: This includes checking the circuitry system that should have the correct rating for the wires, which in this case is 8 AWG or higher to accommodate for targeted loads and distances.

- Installation of the Transfer Switch: This ensures the switch is found with a size that accommodates the generators capacity and adheres to UL requirements.

By methodically integrating these technical particulars and satisfying technical permits, my goal is to have these work processes carried out in a compliant manner with a high degree of professionalism.

Can I save money by installing a generator myself?

Risks and challenges of DIY generator installation

If I were to install a generator myself, some significant risks and challenges could compromise safety, functionality, and compliance. One major concern is ensuring the correct sizing of the generator, which requires calculating the total load demand, including starting watts for appliances, to avoid overloading the system. Incorrect installation could result in electrical hazards such as backfeeding, a dangerous condition that can endanger utility workers and damage equipment.

Also, adhering to local building codes and electrical practices such as the NEC and UL is essential, but because of the lack of technical know-how, it becomes impossible. For instance, effective generator grounding and the installation of an adequate transfer switch that meets the generated unit’s nominal safety (30A or 50A in prevalent usage) are essential for safety and efficiency.

Do-it-yourself installations also encompass difficulties like fuel line connections for gas-powered devices which have to ensure proper venting and pipe sizing for both the propane and natural gas systems. These difficulties, when coupled with a lack of proper tools, technical knowledge, and permits greatly increase the chance of poor performance or equipment failure.

In the end, even though I might be able to save money in the short term by trying to install a generator on my own, the possibilities of non-compliance, damaging the equipment, and having safety issues make it a lot less practical and safe than hiring an appropriately qualified professional.

Cost Comparison: professional vs. DIY installation

When evaluating the cost of professional generator installation versus a DIY approach, several factors must be considered. Professional installation typically includes labor, materials, and warranty support, which collectively ensure compliance with safety standards and local codes. On the other hand, a DIY approach may initially seem cheaper but can lead to unforeseen expenses such as specialized tools, permits, and potential correction of installation errors.

For instance, the cost of professional installation for a standard 10kW standby generator may cost between $3,000 and $5,000. Other factors such as site conditions and local labor rates will further influence these costs. Additional costs are incurred for load calculations, proper connections to the transfer switch, proper venting, and fuel line installation. Trying to undertake this as a DIY project may reduce the costs from $3,000 to $5,000 to a mere $1,000-2,000 in materials and necessities. However the likelihood of operational faults increases tremendously.

- Optimization: The generator’s proper sizing is crucial to overcoming the issues of overload on the generator which will result in seamless operation.

- The size of the fuel line: a deficiency in the size of the required fuel line may hinder fuel from efficiently passing into the intended system which will result in equipment malfunction or complete failure.

- Installation of the transfer switch: the transfer switch needs to be specially designed to comply with NEC codes to avoid any mishandling of the power utility while using the generator.

- Exhaust Venting: There is a danger that carbon monoxide may accumulate as a result of not keeping minimum distances or appropriately venting.

- Permits and Inspections: These are essential in various locations to not infringe local regulations. This adds to the challenge of engaging in DIY activities.

Although professional installation services may seem expensive at the outset, they are worth the investment especially because there are safety, reliability, and technical standards in the latter.

When to hire a professional generator installer

I would undoubtedly advise the use of a generator installer if you come across the following issues:

- Cumbersome Electrical Integration: It is crucial to use a professional generator installer if the installation entails connecting a generator to a residential electrical panel through a transfer switch. This job requires knowledge of wiring and the National Electric Code (NEC). Bad connections can result in backfeeding, which can be dangerous to both utility workers and the household.

- Load Assessment and Sizing: Generator sizing requires expertise. If you cannot gauge appropriate power requirements, hire an expert to calculate the desired load. This includes assessing key appliances and starting wattage.

- Follow Local Authority Compliance: An installer who is familiar with local permits will ensure the installation is compliant and is up to par with zone restrictions, minimum placement distances (5 ft from doors and windows), and other EPA rules regarding emission.

- Fuel System Installation: If your fuel generator consists of propane or natural gas, professional installation is a must. The fuel lines require proper connections and testing – a leaky connection could cause a lack of pressure and fire hazards.

- Safety Considerations: If you are not familiar with the exhaust ventilation needs a specialist has the option of designing the setup so that carbon monoxide does not accumulate. For instance, he or she will place exhaust points no closer than 10 feet to air intakes or places where people live and this will meet safety standards.

By entrusting these obligations to a competent specialist you eliminate hazards, prolong the life of the generator, and make sure that both you are safe and the law is not being contravened.

How do I choose the right size generator for my home?

Matching generator capacity to whole-house requirements

To determine the right size generator to power your home, you need to estimate the total wattage of all the critical appliances that will be in use during a power interruption. First, make a list of the appliances you intend to operate like refrigerators, HVAC, lighting, and other electronic devices. Each appliance will come with a specification label or user manual which will provide you with an estimated rated wattage.

- Starting vs. Running Wattage: A more sophisticated appliance such as yours will have an air conditioner or a refrigerator that will use a higher starting wattage (surge power) than running wattage.

- Continuous Load: All appliances that will operate at the same time require running wattage, so you will surpass the threshold if you keep the rest point at 8000W Generator Automatic Switch On. So, Sitting with your running wattage total at 8000W, the default setting for your generator should be above 10,000W for Avoi overloading a generator.

- Voltage and phase requirements: In your home systems, 240V appliances like dryers or well pumps are operational. Then your generator should check if it provides split phase power at 120/240V for these devices.

- Fuel Efficiency and Runtime: The fuel consumption of a generator can vary according to its capacity. For instance, a 10kW generator usually operates under a load of around 50% which results in a fuel consumption of 1 gallon of propane or gas per hour. Evaluate the model appropriate to your expectations by considering fuel consumption and availability, as well as the runtime parameters.

This can be achieved by ensuring that your power requirements are within the generator’s rated power and other capabilities for safety and performance purposes.

Balancing cost and power output

In this case, I will first explain how I determine my exact power needs to strike a balance between cost and power output. For instance, if I am looking to power certain appliances that have a set watt requirements such as a refrigerator (600-800 watts) or an A/C unit (2,000-4,000 watts) I would figure out the wattage total alongside additional runtime needs.

- Wattage Calculation: Primarily, a power budget is calculated by listing the wattage of all essential devices. For starting or surge wattage, account for devices like motors or compressors, which may require one and a half to three times their running wattage.

- Fuel Type and Consumption: Depending on the fuel consumption type used i.e., gasoline, propane, or diesel can have fuel efficiency payoff. For instance,e a 5K-watt generator has a 50% load and during average runs consumes around 0.75 gallons of gas per hour.

- Runtime vs. Fuel Tank Capacity: Operational needs have to be matched with the fuel availability. Fuel tanks on generators often have 6 gallons, so to ensure efficiency based on average usage, they do tend to have around 8-10 hours of half load.

By aligning these factors with my needs, I can purchase a generator with reasonable operational costs but still delivers power effectively.

What ongoing costs should I consider for a backup generator?

Fuel costs for different generator types

The operating costs of a fuel-powered backup generator differ from one type to another and are dependent on the price of the fuel type being used; the price, availability, and efficiency vary with the type of fuel. Below are detailed insights into fuel costs for the most common generator types:

- Gasoline Generators: The accessibility of gasoline is very high, however, the price is highly dependent on the state of the market and can change greatly. A gasoline generator with a load of 50% uses around 0.75 gallons of fuel every hour, which is very economical for short-duration use, but not so for long term. If proper care is not taken, gasoline has a very low shelf life.

- Propane Generators: Compared to gasoline, propane has much cleaner emissions and a longer shelf life. A standard propane-powered 5000 watt generator at 50% load with a consumption of around 1.6 gallons uses propane at varying rates. Though propane is more expensive, its environmental benefits and stability make it easier to store long-term.

- Diesel Generators: Fueled by diesel, these engines are remarkably more fuel-efficient than gasoline or propane-powered counterparts. The diesel-powered generators have remarkably lower running costs as well. For instance, a 5000-watt diesel generator can run almost at 50% load and only use 0.4 gallons of diesel every hour. Furthermore, diesel fuel is densely packed with energy which drastically reduces the consumption per hour, however, it does require treatment to stop microorganisms from growing while being stored.

- Natural gas Generator: This type has the benefit of a continuous flow of fuel as long as one is connected to municipal pipelines. On the downside however,r their performance is expected to fall off during extreme cold and these generators are definitely not designed for portability.

When trying to find a fuel-cost-appropriate generator, it is critical to take the local fuel prices and expected run time into account along with the operational maintenance of the generator, as it ensures the much-desired operational efficiency and cost-effectiveness.

Regular maintenance expenses

Routine scheduled activities for generators include the change of oil, replacement of filters, coolant filling, and other inspections for operational reliability. The frequency of these activities is determined in combination by the type of generator, the constraints set by the manufacturer, and for example:

- Change Of Oil: These are usually done once every 100-250 hours of operation, or else, annually whichever comes first. Because certain viscosity oils are believed to render the optimal performance; oils of diesel generators have SAE 15W-40 as standard.

- Filter Change: To avoid blockage to air and fuel, filters are supposed to be changed or checked every 200-300 hours of operation to allow efficient combustion.

- Coolant Maintenance: The coolant systems of the liquid-cooled generators need refills or total flushes, as per the guidelines of the manufacturer. This is usually done once every 1,000 hours or annually to prevent overheating.

- Battery Check: Preventive maintenance on batteries behind the starter system and auxiliary use should be checked every month to ensure sufficient charging and electrolyte content where needed.

Following the coverage of the intervals provided above enables the generator to last longer while minimizing repair expenditure. It is advisable to use the owner’s manual for precise specifications and intervals as well as use OEM parts for performance consistency. Additionally exercising proper maintenance aids in the abiding of warranty terms ensuring durability and safety in the long run.

Potential repair and replacement costs

It is necessary to assess the nature of a problem as well as the components affected by it when estimating the costs of repairing and replacing parts in generator systems. From the operational experience as well as industry standards, the estimates appear to be the following:

- Oil and Filter Changes: The cost of oil changes for generators can usually range from $50-$200, depending on factors such as oil grade and generator capacity. Higher-grade synthetic oils are usually more expensive but provide the best performance for longer periods of usage.

- Coolant Repairs: These procedures are estimated to cost $100 to $300. Depending on the extent of repairs needed on hoses with leaks or damage, costs can go up to $500 or above. If a hose has a leak or if there is damage to it, repairs can cost over $500 or even more.

- Replacement of Batteries: The price of generator batteries is typically between $150 and $400. In the case of specialized lithium-ion or AGM batteries, the price can exceed $500. If batteries are checked every month, it helps increase the lifespan of the batteries while also reducing the costs of replacing them.

- Fuel System Repairs: Replacing or cleaning fuel injectors can cost anywhere between $200 and $700. Fuel system components such as the fuel pump require maintenance, or else they can cost $1000 or more to repair, and this is usually the price of the major fuel system components.

- Engine Repairs: Problems with internal parts such as pistons or cylinder heads are expensive, with repairs or replacements typically starting at $2,000 and going upwards depending on the size and complexity of the engine generator.

The costs vary based on the generator power, whether the small kW types are designed to service homes or the bigger MW ones used for industry. Doing scheduled maintenance such as the intervals specified above would reduce the risk of expensive repairs. Always ensure adherence to the manufacturers’ instructions and technical documents during estimates for repairs and replacements.

Frequently Asked Questions (FAQs)

Q: What is the average cost to install a whole-house generator?

A: The average cost to install a whole-house generator typically ranges from $7,000 to $15,000. However, the total cost can vary greatly depending on factors such as the size of the generator, brand, and specific installation requirements.

Q: What size generator do I need for my home?

A: The size of the generator you need depends on your home’s square footage and the appliances you want to power during an outage. As a general rule, you can estimate about 75 watts per square foot of living space. For example, a 2,000-square-foot home might require a 15-20 kW generator. It’s best to consult with a professional generator installer to determine the exact size generator you need based on your specific requirements.

Q: What are the main cost factors for whole-house generator installation?

A: The main generator cost factors include the unit’s size and capacity, brand, fuel type (natural gas, propane, or diesel), installation complexity, permits, and whether a transfer switch needs to be installed. Additional costs may include site preparation, electrical work, and ongoing generator maintenance.

Q: How does the cost of a standby generator compare to a portable generator?

A: Standby generators are significantly more expensive than portable generators. While a portable generator might cost between $500 and $2,000, a whole-home generator can cost $7,000 to $15,000 or more with installation. However, standby generators offer automatic power restoration, greater capacity, and the ability to power your entire home during an outage, which portable generators cannot typically do.

Q: Can I install a home generator myself to save on costs?

A: While it’s possible to install a generator yourself, it’s not recommended due to the complexity of the job and potential safety hazards. Professional installation ensures proper connection to your home’s electrical system, fuel source, and compliance with local codes. Additionally, DIY installation may void the warranty. The cost of professional installation is usually worth the peace of mind and proper functioning of your whole-house generator.

Q: What ongoing costs should I consider for a whole-home generator?

A: Ongoing costs for a whole-home generator include fuel costs (natural gas, propane, or diesel), regular maintenance (which may cost $200-$300 annually), and potential repairs. It’s important to factor in these long-term expenses when considering the total cost of owning a whole-house generator.

Q: How long does it take to install a whole-house generator?

A: The installation of a whole-house generator typically takes 1-3 days, depending on the complexity of the installation, whether a transfer switch needs to be installed, and any necessary site preparation. Factors that can extend the timeline include obtaining permits, weather conditions, and the need for additional electrical work.

Q: Are there any ways to reduce the cost of installing a whole-home generator?

A: To reduce costs, consider getting multiple quotes from different generator installation pros, choosing a smaller unit if appropriate for your needs, and installing during the off-season when demand is lower. Some utility companies or generator manufacturers may offer rebates or financing options. However, avoid cutting corners on quality or professional installation, as this can lead to higher costs and safety issues in the long run.