By keeping the lights on and the essential appliances in your home working, a standby generator has untold worth amid a blackout. But then comes the telltale question from the homeowner: “How much fuel does the generator consume?” Knowing your generator’s fuel consumption is essential for planning, budgeting, and maintaining enough power-running time through the emergency phase. In this article, we will discuss all sorts of things affecting consumption, compare generators, and offer tips to optimize the effectiveness of a standby power system. Whether preparing your home for an incoming storm or just curious about operating costs, knowing how efficient your generator is will keep you one step ahead.

Understanding Generator Fuel Consumption

Major factors impacting generator fuel consumption include:

- Load Level: Fuel consumption depends mainly on the power supplied by your generator. Generally, a greater load means heavier fuel consumption.

- Generator Type: Diesel generators are usually more fuel-efficient than gasoline generators and give longer run times for each gallon.

- Size of the Generator: The larger the generator, the higher the fuel consumption, but larger generators may still run more efficiently under heavy loads than smaller-capacity units.

- Maintenance and Condition: Properly maintained generators are more efficient than those that lack maintenance and are, therefore, less fuel efficient.

Understanding these factors and employing prudent energy management will undoubtedly increase generator efficiency and cut costs.

What is Generator Fuel Consumption?

Fuel consumption in a generator refers to the amount of fuel the machine uses to produce a certain amount of power or energy. It is generally measured in gallons or liters per hour, depending on how much is being made, as the load varies, the generator size, and the generator’s efficiency.

Factors Affecting Fuel Efficiency in Generators

|

Factor |

Description |

|---|---|

|

Fuel Type |

Propane, gasoline, and diesel differ in efficiency. |

|

Generator Size |

Larger generators use more fuel for operation. |

|

Load |

Higher loads increase fuel usage dramatically. |

|

Maintenance |

Poor maintenance leads to higher fuel consumption. |

|

Age of Generator |

Older models are less fuel-efficient than newer ones. |

|

Environmental Conditions |

Extreme temperatures can reduce generator efficiency. |

|

Altitude |

Higher altitude reduces efficiency due to thinner air. |

|

Ventilation |

Insufficient oxygen increases fuel consumption. |

|

Carbon Deposits |

Build-up reduces engine efficiency and raises consumption. |

|

Generator Efficiency |

Efficient models consume less fuel during operation. |

|

Cooling Temperature |

Incorrect cooling leads to incomplete combustion. |

|

Type of Generator |

Standby units differ from portable units efficiency-wise. |

|

Overloading |

Overloaded units consume more fuel. |

|

Underloading |

Running below 50% load increases fuel wastage. |

How Fuel Type Influences Generator Use

Fuel type greatly determines generator performance and operations, affecting efficiency, emission levels, and operational costs. The analysis below elaborates on various types of fuel influencing generator utilization, backed by data and insights from recent industry trends.

1. Diesel Fuel Generators

Diesel generators are very much in demand in all industrial and commercial applications due totheir efficiency and durability. Diesel is said to have higher energy density than gasoline; therefore, for the same amount of power production, diesel generators use less diesel. Diesel engines use approximately 0.4-0.5 gallons of fuel an hour for 10 kW of power, as revealed by a 2023 industry report. Some disadvantages include high capital or initial cost and the emitted pollutants, though present mitigation technologies, such as Tier 4 engines, try to minimize such impacts.

2. Gasoline Generators

Gasoline generators have always been the choice of lubrication for small portable power backup for home use, garages, retail stores, etc. However, fuel consumption per kilowatt hour is higher in these units than in diesel generators; their average fuel consumption is about 0.75 gallons per hour in units of 7.5 kW. Also, gasoline is very volatile at high temperatures and essentially cannot be stored for long periods; these considerations affect its utility as a solution for power supply.”

3. Natural Gas Generators

Natural gas is increasingly becoming the fuel for standby and backup power systems because of its continuous supply through a pipeline. That said, natural gas plants are considered less polluting compared to their counterparts running on diesel or gasoline. By comparison, they consume between 9,000 and 12,000 BTUs of natural gas per kWh, making them cost-effective in areas where natural gas is cheaply available. Inconsistency in pipeline connection, however, limits their applications.

4. Propane Generators

That is a clean-burning type and is used widely in residential as well as commercial applications. A 10 kW generator consumes about 1.2 gallons of propane per hour, thus putting it on a fuel efficiency level inferior to diesel and natural gas. However, propane boasts infinite shelf life and is excellent for long-term storage and intermittent use in remote locations isolated from a natural gas supply.

5. Renewable fuel generators (Biodiesel and Hydrogen)

Renewable fuels are the new agents for sustainability. In the understanding of the U.S. Department of Energy, biodiesel generators could cut carbon emissions by 86% compared to traditional diesel generators. Hydrogen fuel cells allow a zero-emission avenue, yet the implementation remains a wild card because of challenges to cost and infrastructure.

Key Considerations Based on Fuel Type

|

Fuel Type |

Efficiency |

Cost |

Environmental Impact |

Availability |

|---|---|---|---|---|

|

Diesel |

High |

Moderate-High |

Moderate-High (improving) |

Widely Available |

|

Gasoline |

Moderate |

Moderate |

High |

Widely Available |

|

Natural Gas |

High |

Low |

Low |

Pipeline Access Required |

|

Propane |

Moderate |

Moderate |

Low |

Moderate Availability |

|

Renewable Fuels |

Moderate |

High |

Very Low |

Limited Availability |

Understanding these details helps select a generator that aligns with your power needs, budget, and environmental priorities. By carefully balancing these factors, you can optimize generator performance while reducing long-term operational costs.

Comparing Fuel Types for Standby Generators

|

Fuel Type |

Pros |

Cons |

|---|---|---|

|

Gasoline |

Easy to find, portable |

Shorter shelf life, flammable, less efficient |

|

Diesel |

High efficiency, durable, long shelf life |

Noisy, higher emissions, needs proper storage |

|

Propane |

Clean-burning, long shelf life, easy to store |

Less efficient, requires multiple tanks for large use |

|

Natural Gas |

Cleaner combustion, continuous pipeline supply |

Dependent on utilities, costly installation |

|

Bi-Fuel (Gas/Propane) |

Versatile, allows switching fuel sources |

Conversion kits required, availability varies |

Natural Gas: Pros and Cons

Due to its availability in most parts of the country, flexibility, and green image, natural gas remains one of the most sought-after fuel options for standby generators. Let’s explore the pros and cons:

Pros of Natural Gas

- Reliable Supply

Since natural gas pipelines deliver gas directly to homes and businesses, they ensure an uninterrupted flow of fuel for use. In contrast to diesel or propane, there is never any great need to keep a store of these gases on site; this can often come in handy in times of prolonged power outages.

- Down to Earth Costs

Natural gas costs tend to be lower than other fossil fuels. Studies have shown that the price per million BTU ranges from $6 to $12, depending on the locality, so it works out cheaper from a long-term perspective. Also, maintaining a generator powered by natural gas may require less expenditure simply because the combustion process is comparatively cleaner.

- Environmentally Safe

When natural gas is considered as a source of power generation, the emissions consist of CO2, which is 50-60% less compared to the emissions from coal, according to the U.S. Energy Information Administration (EIA). In addition, it produces fewer sulfur dioxide and particulate emissions, thus enhancing air quality.

- Convenience

Gas distribution in many cities and suburbs has an established network. Hence, fuel deliveries and site storage are not needed, which mitigates a few logistical concerns and hazards.

Cons of Natural Gas

- Dependence on Infrastructure

While pipelines crisscross many populated states, the network doesn’t extend to some rural or remote areas, limiting accessibility. Moreover, in the event of a natural calamity, be it an earthquake, rupture, accident, or leak, may damage the pipeline, either temporarily or permanently, cutting off the fuel supply.

- Installation Costlier

Installation for natural gas standby generators can be more expensive from day one compared with all others simply because pipeline plumbing and connection are involved. However, this is offset by much lower operating costs per hour over time.

- Price Volatility

Generally, natural gas is cost-effective, yet its price changes with demand fluctuations: during winter months, when heating needs increase, prices will be high. This volatility adds challenges to fixing long-term operating costs.

- Environmental Impact

While less polluting than other fossil fuels, natural gas is not renewable. Any methane leakage, which constitutes most of natural gas, during its production or transportation, will promote global warming.

Key Data Points:

- Emission Reductions: The reduction in carbon dioxide emissions from a natural gas generator is about 25-30 percent compared with propane generators.

- Fuel Efficiency: A typical natural gas generator uses around 7 to 11 cubic feet of gas for every kWh while on standby applications.

- Pipeline Reach: The natural gas pipeline system is said, according to the U.S. Department of Transportation, to cover over 300,000 miles, making it one of the largest systems in the world.

Final Thoughts

Natural gas is the fuel of choice for consumers who require a fuel-efficient, reliable, and green source of emergency power. Therefore, one should evaluate whether infrastructure is available for this green fuel and any fluctuations in price that may be associated with it. After consulting those pros and cons, the end user can decide if natural gas fits their operational needs and priorities.

Propane: Advantages and Disadvantages

Propane is a multifaceted energy source, with its efficiency and portability commonly regarded as attractive features. Here are some more specifics of its pros and cons:

Advantages of Propane

- High Energy Efficiency

Propane, with a much hotter flame than natural gas, is a highly efficient fuel source for heating, cooking, or powering equipment: it almost provides 2,500 BTUs per cubic foot, compared to 1,000 BTUs per cubic foot supplied by natural gas.

- Portability and Storage

Propane can be stored in tanks and transported to areas where no natural gas pipeline infrastructure exists. This is especially useful for rural or off-grid locations.

- Easy on the Environment

In particular, propane is one of the few fuels that burns cleanly, emitting far less greenhouse gases than gasoline and diesel fuels. The PERC states that propane actually emits 12% less CO2 than gasoline.

- A Reliable Energy Source

Propane-based technologies do not need a continuously running gas pipeline. Storage on-site may provide energy in the event of outages or natural disasters.

- Wide Range of Applications

Propane actuates various types of systems, from heating a house to running vehicle engines or operating portable generators, making it a versatile energy solution for domestic, commercial, and agricultural requirements.

Disadvantages of Propane

- Higher Cost Per Unit of Energy

While rich in energy, propane can sometimes be more expensive per BTU than natural gas, depending on consumer market dynamics.

- Storage and Handling Requirements

Propane has to be stored and handled in tanks under special conditions; these special storage conditions may increase their operational expenditures and maintenance liabilities.

- Fewer Infrastructure Options

Distribution of propane is reliant on tank delivery, unlike natural gas, which is held up by pipelines, thereby facing supply delays in remote locations.

- Possibility of Leaks and Explosions

Propane is a great safety risk if it leaks, for it is a highly flammable gas. It is heavier than air and tends to pool in low-lying areas.

- Limited Efficiency in Extreme Cold Conditions

In icy conditions, propane can encounter difficulties, as it must maintain a certain temperature to vaporize from its liquid state to be used as a fuel source.

A careful look into the advantages and disadvantages will allow users to decide whether propane suits their energy requirements, basic cost level, accessibility, and operational considerations.

Diesel Fuel: Cost and Efficiency Considerations

Diesel for energy entails cost and efficiencies highly dependent on how it is used and in what circumstances. Diesel oil generally boils down to being more fuel-efficient than other alternatives, allowing for greater mileage and longer operation durations for machinery. A little off-putting is that the price per diesel oil fluctuates a lot with market situations, making cost predictability somewhat subjective. Balancing these two becomes my key to deciding whether diesel is the best option using particular energy needs.

Estimating Fuel Usage for Generators

To estimate fuel consumption for the generator, first, find the fuel consumption rate for the generator. This data is normally mentioned in the manufacturer’s specifications, with GPH at percent loads. Second, find out the load your generator will carry during operation. Third, calculate the total fuel by multiplying the fuel consumption with the hours of operation. For instance, a generator consuming fuel at 0.75 GPH at 50% load for close to 10 hours would fairly need about 7.5 gallons of fuel. However, allow some time for safety to consider some potential variations in load or efficiency.

Calculating Fuel Consumption Rates

Using the latest data from Google mentioned above, fuel consumption rates are calculated by taking the generator fuel consumption/hr at expected load, multiplying these values by the hours of operation, and then including a safety margin for correctness.

Understanding Full Load vs. Partial Load Usage

When operating a generator, it is crucial to understand the differences between full load and partial load usage to maintain good fuel efficiency and proper generator performance. Usually, whole load operation has higher fuel consumption rates and is essentially maximum generator capacity working on maximum electrical loads. Partial load operation refers to all operations below a generator’s full load rating. On the one hand, partial load consumes less fuel, but if it is too low, it may lead to poor fuel efficiency.

Full Load Operation

According to data from recent online queries, most full-load generators consume 0.6 to 1.0 gallons of fuel per hour per 10 kW in different models and fuel types. For example:

- When operating at full load, a 10-kW diesel generator might consume 0.8 gallons per hour.

- When operated at full load, a 20-kW gasoline-fueled generator might require about 1.7 gallons of fuel per hour.

Remaining at full load may ensure the generator produces maximum power and is perfectly suitable for short-term installation, but if long-term use is done without intermittent maintenance, it can significantly reduce the equipment’s life.

Partial Load Operation

The following are some suggestions about less-than-full-load operation concerning fuel efficiency. Data reveals:

- A 10-kW generator under 50% load uses about 0.4 gallons of fuel per hour, decreasing fuel consumption by up to 30% compared to that of full load.

- Generators below 30% load may be fuel inefficient and suffer wet stacking; this is the buildup of unburned fuel in the engine over time, which can eventually damage the engine.

Some Important Points

For a generator to perform optimally:

- Run generators at 50% and 75% load ratings to ensure consistent and efficient fuel consumption.

- Always calculate fuel requirements quickly as load changes, relying on verified data such as the manufacturer’s specifications and real-time benchmarks.

- Avoid sustained operation below 30% load to lessen future maintenance troubles.

Practicing these may help you get the highest efficiency from your generator, prolong its life, and lessen operational costs.

Cost Estimates for Different Fuel Types

|

Fuel Type |

Daily Operating Cost |

Initial Setup Cost |

Remarks |

|---|---|---|---|

|

Gasoline |

$52/day for 5kW generator |

$500–$3,200 |

Fluctuating fuel prices, moderate efficiency |

|

Diesel |

$122/day for 20kW generator |

$3,200–$24,000 |

Efficient, higher maintenance costs |

|

Propane |

Over $200/day for 20kW generator |

$600–$21,000 |

Clean-burning, long shelf life |

|

Natural Gas |

$20–$40/day for 15kW generator |

High installation cost |

Reliable pipeline supply, cost-effective |

|

Solar |

Negligible with sunlight |

$3,000+ |

One-time cost, eco-friendly |

Optimizing Fuel Usage in Generators

- Perform Regular Maintenance

The generator must be maintained for excellent performance and fuel efficiency. Maintenance includes cleaning filters, checking the coolant levels, and inspecting for wear and tear of any components.

- Match Load to Capacity

The generators should be operated around recommended load levels because low or relatively higher capacities increase fuel consumption.

- Use Quality Fuel

Fueling with the manufacturer-recommended fuel grades will respect its efficiency and reduce the damage of the system.

- Schedule Usage Efficiently

Using the generator only in essential and chosen operations will help avoid using unnecessary fuel.

- Leverage Automation Features

If the generator has automatic load-balancing and shutdown functions, use them to minimize fuel wastage during periods of idleness or low demand.

Following the above steps will help reduce fuel costs, minimize fuel wastage, and keep the generator running reliably.

Tips for Reducing Fuel Consumption

|

Tip |

Description |

|---|---|

|

Service Generator Regularly |

Reduces wear and ensures efficient operation. |

|

Avoid Overloading |

Prevents high fuel usage and potential damage. |

|

Remove Carbon Deposits |

Improves burning efficiency, lowers fuel waste. |

|

Maintain Coolant Temperature |

Ensures proper combustion and reduces fuel use. |

|

Use Necessary Equipment Only |

Minimizes load and fuel consumption. |

|

Optimize Load Capacity |

Avoid underloading or overloading the generator. |

|

Ensure Proper Ventilation |

Improves combustion efficiency and reduces waste. |

|

Use High-Quality Spare Parts |

Enhances generator efficiency and durability. |

|

Use Alternative Power Sources |

Reduces dependency on fuel-based generation. |

|

Store Fuel Properly |

Prevents degradation and maintains fuel quality. |

Regular Maintenance for Better Fuel Efficiency

Fuel efficiency in generators cannot be improved without timely maintenance. For me, this meant scheduling routine servicing so that every component, such as filters and spark plugs, was cleaned and checked for proper functioning. I also inspected fuel lines for leaks and kept the generator working under proper load conditions. Simple steps like these have kept my equipment running longer with low fuel consumption.

Choosing the Right Generator Size

Choosing generator size requires understanding your power needs. I start by listing the devices or systems I want to run and calculating their combined wattage requirements for starting and running. Once I have a total, I add a safety margin so that the generator can absorb surges. Now that I apply this method, I am able to select the one that meets my needs efficiently without overloading or wasting fuel.

Frequently Asked Questions about Generator Fuel Use

| Question | Answer |

|---|---|

|

What type of fuel should I use? |

Follow the owner’s manual for fuel recommendations. |

|

Can generators run continuously? |

Yes, with proper maintenance and fuel refills. |

|

How long can gasoline be left in? |

Maximum two weeks or use a fuel stabilizer. |

|

Should I use a fuel stabilizer? |

Yes, for storing fuel longer than a few weeks. |

|

Can I convert to dual-fuel? |

Recommended to buy a dual-fuel generator instead. |

|

Is grounding necessary? |

Yes, to avoid electrical shocks and ensure safety. |

|

Can I store fuel long-term? |

Store in a cool, dry, ventilated space. |

|

What happens if overloaded? |

Circuit breakers trip to protect the generator. |

|

Can I run indoors with ventilation? |

No, toxic fumes can still build up indoors. |

|

Should I use ethanol-blended fuel? |

Avoid fuels with more than 10% ethanol (E10). |

How Much Natural Gas Does a Generator Use?

Typical generators consume around 7 to 13 cubic feet of natural gas per kilowatt-hour of electricity generated. The figures are, of course, subject to the size and load on the generator.

How Much Propane is Required for My Generator?

Propane requirements depend upon generator size and load. For example, my generator needs about two to three gallons of propane per hour at full capacity. However, your usage might differ, depending on how efficient the generator is and the electrical demand placed upon it.

What Gas Does a Generator Use?

Engines usually use gasoline, diesel, natural gas, or propane, depending on the generator’s design and intended use.

References

-

Getting serious about safety and loss prevention emergency power and standby generators – A resource from Texas A&M University discussing backup generators and their fuel requirements.

-

System architecture design of a robust heating system – A study from MIT that includes insights into natural gas fuel cells and standby generator systems.

-

Coping with power failures – An educational resource from Oregon State University addressing power outages and generator use.

Frequently Asked Questions (FAQ)

How much gas does a Generac generator use per hour?

The fuel consumption of a Generac generator can vary based on its size and load demand. Typically, a 22kW Generac generator uses approximately 2 to 3 gallons of propane per hour during operation at full load. Using natural gas may consume around 200 to 300 cubic feet of natural gas per hour, depending on the required power output.

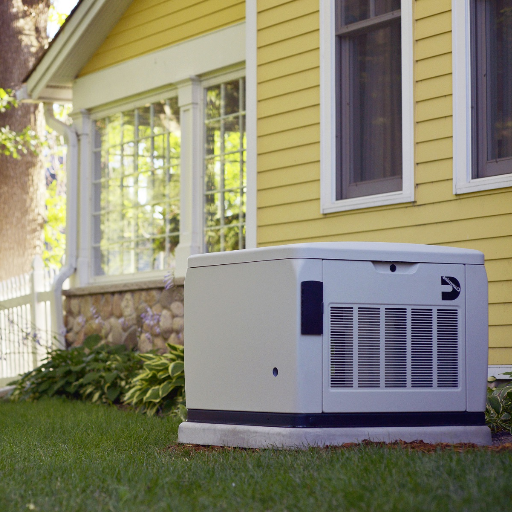

What types of generators are available for home use?

Several types of generators are available for home use, including portable generators, inverter generators, and standby generators. Standby generators, such as the Generac models, are permanently installed and automatically provide power during a power outage. In contrast, portable generators can be moved and used for various appliances but require manual setup.

How does the size of the generator influence fuel consumption?

The size of the generator directly affects its fuel consumption. Larger generators typically consume more fuel because they are designed to handle higher load demands. For instance, a 22kW generator will use a significant amount of fuel when powering multiple appliances compared to a smaller generator that may only run a few essential devices.

How can I enhance fuel efficiency for my backup generator?

To enhance fuel efficiency for your backup generator, ensure it is properly maintained and serviced regularly. Additionally, running the generator at optimal load levels, avoiding overloading, and considering an automatic standby generator can significantly improve fuel economy. Using high-quality fuel can also contribute to better performance.

What is the idle fuel consumption of a home generator?

When not under load, a home generator still consumes fuel, known as idle fuel consumption. This amount can vary, but generally ranges from 0.5 to 1 gallon of propane per hour or around 20 to 30 cubic feet of natural gas per hour for standby models. Understanding this can help you calculate the overall fuel costs during operation.

How do I determine how much fuel my generator will use?

To determine how much fuel your generator will use, consider its size, fuel type, and the load demand. Most generators have specifications that outline fuel consumption rates based on different operating conditions. Monitoring your generator’s usage during operation can also provide insights into fuel needs.

What factors influence the gas bill when using a natural gas generator?

Several factors influence the gas bill when using a natural gas generator, including the generator’s size, the length of time it runs during a power outage, and the current cost of natural gas. Additionally, the efficiency of the generator and how well it is maintained can also impact overall gas consumption and costs.

How much propane is needed for a power outage?

The propane needed during a power outage depends on the size of your generator and the outage duration. A typical home standby generator may consume around 2 to 3 gallons of propane per hour. Therefore, for a 10-hour outage, you would need approximately 20 to 30 gallons of propane, depending on the load being powered.