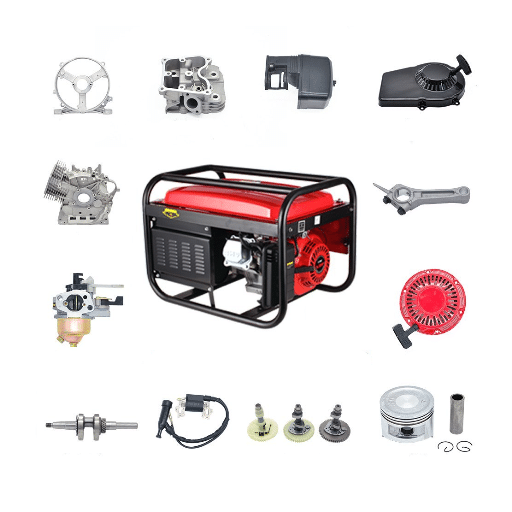

Generators are considered a central tool that makes sure there is a continual supply of energy, be it for houses, businesses, or entire industries. The most important thing in order to achieve maximum utilization and efficiency of generators is to understand the machinery’s components. In a typical generator, the engine, alternator, control panel, and cooling systems are the essential elements among others, and each has a vital share in the entire process of converting mechanical energy into electrical power. This article examines the generator parts, giving a comprehensive coverage of their functionalities, maintenance needs, and signs of wear to be on the lookout for. You can benefit from this tutorial whether you already have a generator in place that you wish to manage well, or you are thinking about purchasing one, since it imparts to you the know-how to make the right choices and ensure that the device is always reliable, regardless of the situation.

Understanding Main Generator Parts

Engine

The motor is one of the most important technological innovations of the generator. It is this motor that gives the power to the alternator, and the capacity of the latter is mainly a function of both of the latter parts. To have proper maintenance, such as changing oil and checking fuel, is a precondition to the effective operation of the generator.

Alternator

It is the alternator that converts the mechanical power, which the engine produces, into electrical power. The alternator consists of a rotor and stator, working together to produce an electric charge. The system’s wear is directly related to the alignment of the parts and their proper inspection. This is also a prerequisite for the machine to achieve the status of electricity production at a constant rate.

Fuel System

The fuel system contains stored and supplied fuel for the engine. It consists of the main parts such as the fuel tank, pump, and injectors. It is a must that the fuel lines should be inspected regularly and they should transport the clean fuel to avoid clogging and any unwanted troubles in the engine.

Cooling and Exhaust Systems

Generators emit heat while working and the cooling system protects the components from overheating. The exhaust system does the same by safely removing harmful gases such as carbon monoxide and ensuring that the operation is safe.

Control Panel

Accessing the control panel can let you monitor the generator and handle its operations. Not only does the control panel show statistics such as voltage, frequency, and operating temperature but also it may have an overheat function to stop the process.

Battery System

The batteries are the first to provide the power for the generator to be started. Regular charging and testing make sure that the cell continues to be working and there is no failure due to the source of emergency.

Overview of Generator Components

| Component | Function |

|---|---|

| Engine | Converts fuel to mechanical energy. |

| Alternator | Converts mechanical energy to electrical energy. |

| Fuel System | Stores and delivers fuel for operation. |

| Voltage Regulator | Maintains consistent voltage output. |

| Cooling System | Prevents overheating during generator operation. |

| Lubrication System | Reduces friction between moving parts. |

| Exhaust System | Removes harmful gases from engine. |

| Control Panel | Monitors and manages generator performance. |

| Battery System | Supplies power for startup process. |

| Frame/Enclosure | Provides structure and protection for components. |

| Circuit Breaker | Protects against electrical overloads. |

| Automatic Transfer Switch | Transfers power between sources automatically. |

Importance of Compatibility in Replacement Parts

It is very important to maintain the compatibility of replacement parts with the running machinery or equipment for the reason of efficiency, safety, and durability. It is a big problem when the parts do not meet the original specifications very accurately because it usually results in the mechanical stress, the decreased performance and even the safety hazards. For instance, wrong parts might be selected for an electrical generator that will cause the system not to run or even get burnt. Usage of the incompatible parts can be wide in terms of the impact on the machine. For one, the warranties will not be valid, maintenance costs might rise, and the whole system could be destroyed earlier than it should.

One specific task is for makers of replacement parts to work out the materials, dimensions, and tolerances perfect for their equipment. Therefore, breaking even slightly, no one’s going to give you as much good as electronic or mechanical systems. It is critical that you are guided by the manufacturer’s manual in the case of parts and that you can have the part inspected in terms of the necessary standards, certificates, and regulations for compliance, as also in terms of the proper functioning of the equipment. In the end, the use of high-grade, parts that are alright for this purpose only translates to less downtime, increased reliability, and the best performance in all operating conditions.

Maintenance of Generator Parts

Important: It is necessary to have a regular generator parts check up in every 6 months or 200 hours of running time – whichever comes first. Through regular inspections, early signs of damage, possible failures, and wear can be detected easily and rectification can be done in a timely manner. Most attention should be paid to the crucial parts of the generator, such as fuel and air components, lubrication, and electrical circuits. The complete schedule recommendation by the maker should be adhered to, with the supplement of the inspections done after the difficult situations and heavy use, for the sake of keeping the power and performance dependable.

Critical Maintenance Practices for Generators

Proper Lubrication

Proper lubrication is vital to a smooth and long-lasting performance of a generator. The presence of engine oil decreases the friction, and thus the moving parts wear, and ensures the most suitable operation during different situations. The oil changes should be made according to the manufacturer’s instructions which is usually every 100 to 200 operating hours or upon the oil condition monitoring system indication. The proper oil with the right grade and viscosity quality must be used to make sure it is working well in the most common and extreme situations. On the other hand, changing the filter together with the oil is a must as it allows to keep the lubrication clean and efficient by protection from metal particles, dust, or any other debris.

Cooling System Management

The proper condition of the cooling system is of the utmost importance in maintaining the generator’s temperature at an acceptable level; be it with the generator continuously running or putting out a high power level. The radiator, the cooling fins, and the hoses need to be inspected regularly for any obstruction, physical damage, or leakage. The system should be given free flow by removing the gathered dust or dirt by blowing it out or washing it with compressed air or the appropriate cleaning agents so that the cooling efficiency will be increased. Coolant level check should be done regularly to make sure the system is in the right environmental condition or corrosion will be avoided and heat transfer will occur properly.

Regular Inspection of Essential Components

To keep the generator functioning properly, one needs to keep on checking the key components and thus keep the generator efficient, safe, and reliable in the long run. The most critical point that needs to be on top of the list is the fuel system, and the entire system should be inspected for the presence of leaks, blockages or impurities. For optimal combustion and power generation, fuel with good quality and filters that are clean are the basic requirements. The battery is also a critical component and it has to be examined for voltage levels, electrolyte levels, and terminals in order to have a constant starting power. The electrical connections of the generator must be checked the most thorough way possible for any signs of corrosion or loose connections for these things could have a very negative effect on the overall performance of the system. Besides, the exhaust systems need to be looked at for leaks and signs of wear in order to minimize the emission of dangerous gases and remaining in compliance with the regulations.

Creating a Maintenance Schedule

Living up to the task of creating an all-encompassing maintenance program for generator parts is imperative for the achievement of optimal, prolonged performance as well as the observance of safety regulations. The maintenance program should be based on the manufacturer’s stance, on the operational environment, and on the global climatic situations. The most important parts such as air filters, fuel filters, oil filters, belts, and spark plugs are to be inspected regularly and replaced when their working time (in hours) or calendar periods expire. For instance, the engine oil and oil filter are usually changed after running the generator for 100-250 hours or once a year at least, depending on the model and utilization.

Checking coolant levels and performing system flushing on a regular basis are also necessary for avoiding overheating and corrosion. Apart from that, the health of the battery and its connections must be verified on a monthly basis to ensure there is enough charge and for the risk of power failure to be taken away. The exhaust systems that are crucial for the emission-safe ventilation process should be examined for damage, blockage, or leakage no less frequently than at 6-month intervals, and any overlooked issues can cause severe operational hazards.

Use of the most advanced diagnostic equipment will equip scheduling with more accurate data-driven insights, and at the same time, wear trends will be recognized beforehand as diagnosis will become more predictive. Furthermore, detailed logs about maintenance work will guarantee that no maintenance tasks will be left out and could also be used as a record when the matter of warranty arises. Having a maintenance strategy that is specifically tailored to the needs and at the same time is consistent shows how valuable it is in order to reach both reliability and efficiency in generator operations.

Identifying High-Quality Replacement Parts

OEM vs. Aftermarket Generator Parts

| Feature | OEM Parts | Aftermarket Parts |

|---|---|---|

| Quality Assurance | High, factory-tested | Varies by manufacturer |

| Compatibility | Exact fit for specific models | May require adjustments |

| Warranty | Typically includes robust warranty | Warranty may vary or be limited |

| Cost | Usually more expensive | Generally less expensive |

| Availability | May require special ordering | Often more readily available |

| Longevity | Designed for long-term use | May have shorter lifespan |

| Manufacturer Support | Backed by the original maker | Limited or third-party support |

| Regulatory Compliance | Meets industry standards | Compliance depends on supplier |

| Installation | Simplified,designed for exact match | Installation may need modifications |

| Customization | Limited customization options | More variability in design |

Signs of Inferior Replacement Components

The low-quality generator replacement components can be easily recognised through the material quality and the differences in the manufacturing process. Bad materials like metals of low grade or plastics of poor quality could lead to decreased durability and poor heat resistance, which would result in an earlier part failure. Apart from this, there can be apparent manufacturing defects like uneven finishes, machining errors or misaligned parts that could show the presence of poor workmanship.

The lack of the required certification or conformity labels, such as those bestowed by the ISO or other reputable organizations, is another main point of concern. Parts without these seals compatibility may compromise the safety and efficiency of the operation of the generator compared to the industry required standards. Furthermore, the variation of the performance metrics, e.g., voltage regulation or current stability, is a good parameter to reveal the poorly designed or untamed components.

It can also be said that good packaging serves as a mirror. On the one hand, the authentic product supplies customers with abundant, clear, and accurate information in the form of manuals and specifications, while on the other, the imitations are not that helpful; they are either too brief or too obscure in the explanations. Besides, if the prices are extremely cheap, then it may be because the product is a counterfeit or low-end product, strongly recommending checking meticulously before making a purchase.

Finding the Right Generator Parts: Tips and Resources

It is very important to be guided by the authoritative suppliers and the trustworthy manufacturers who have already been delivering the highest quality and most reliable products. The search for such suppliers should begin with going to the official websites of OEMs (Original Equipment Manufacturers) which normally contain the lists of verified products, that is, the products that are compatible, and the different ways of purchasing. For third-party suppliers, the customers’ feedback and the ratings and the presence of any certificates that indicate the compliance with the area’s standards such as ISO certificates or safety marks can serve as good examples of what to look for.

It is of importance that one uses the most recent tools of the digital era to locate the correct parts of a generator with ease. There exist several online platforms which are reputable and provide tools to search for parts with a high degree of efficiency. The search engine on these platforms lets the user filter their options according to model numbers, specifications, or compatibility with various generator brands. On top of all that, the process of determining if the part numbers are correct by searching through the manufacturer’s databases can also be an option. Some of these major sources include the use of detailed part diagrams or even 3D models in search and thus can make the process faster and accurate.

Pro Tip: One might get a fair judgment of the various features’ and quality’s impact through technical forums, industry websites, and user-focused review platforms. The user feedback that you can find on these sources will probably include in-depth evaluations, thus showing the true-to-life performance and the lifespan of different items. Users’ experience with the installation, compatibility issues, and other unexpected factors may also be discussed here, which are beyond the scope of the official specifications of the manufacturer.

Specialized Generator Accessories

Your generator becoming more efficient and reliable really depends mostly on these specialized generator accessories. The automatic transfer switches (ATS) will help you get through power outages smoothly and the fuel stabilizers will keep your fuel in good shape and avoid deterioration. To maintain the generator in the best possible condition, maintenance kits will provide you with filters and spark plugs at all times. And, remote monitoring systems are even a better option, ensuring they offer you updates in real-time, which will not only help you see how your generator is doing but also allow you to address issues immediately. That makes it clear that the right accessories going with your generator assure the best compatibility and functionality. The components are always from reliable manufacturers with a high reputation for being quality and durable.

Transfer Switches and Their Importance

Transfer switches are a really important part of every backup power apparatus. They make a proper switch between the utility power and the power source of a generator during a power outage. The main operation of transfer switches is to take the generator off the main grid and therefore stop the dangerous practice of “backfeeding”- a scenario that can harm utility workers and equipment. The two major transfer switches are: the manual and the automatic. With the manual ones, a person has to physically change the switch to transfer power, while the automatic transfer switches (ATS) sense the power disruption and switch to generator power almost immediately without the need for user interference.

The best thing about automatic transfer switches nowadays is that they come with hi-tech sensors and microprocessors that keep track of the voltage level and frequency, thereby supporting a constant power supply. Besides, these transfer switches are created in accordance with the industry standard, e.g., UL 1008, which certifies their safety and reliability. Without the right size of a transfer switch, it would be impossible to make it work with the generator and at the same time be able to manage the load effectively and economic. Furthermore, another vital part is to frequently maintain and test the transfer switch so as to ensure it performs as expected in critical conditions.

Filters: Types and Maintenance

It is essential that filters are in good condition in order for different systems to remain efficient and long-lasting. These tasks are achieved through the removal of impurities and contaminants. The usual filters that are found in the market are air, oil, and water filters, and they all differ in terms of design as they are intended for specific applications. Air Filters are one of the most common types of filters, used, for example, in automotive engines, and their function is to get rid of dust, pollen, and other particles that are in the air. This not only keeps the air inside the room clean but also improves system performance. The filters separate solid particles from oil. Thus, oil filters are crucial elements in the oil loop which involves the pump, well, and other parts of the automotive or engine system.

Optimal filter performance is ensured through proper maintenance schedules. The system of regular checks must be maintained to recognize clogging and wear, which have the effect of decreasing operation effectiveness and adding to the overloading of the system. Following the manufacturer’s instructions and cleaning or replacing filters at recommended intervals will maintain efficiency and avoid interruptions or repair costs. The newer systems with the most modern monitoring equipment teach us that one can be aware of the condition of the filter instantly, and the possibility of thus preplanning the maintenance schedule leads to higher operational dependability.

Chargers and Controllers for Enhanced Performance

Chargers and controllers serve as the main components of energy management systems, but mostly in the case of renewable energy and batteries. Chargers of good quality are specifically designed for the exact and precise regulation of the energy to produce optimal charging profiles that are exactly what different battery chemistries like lithium-ion or lead-acid need. In this way, the battery life span will be increased, and battery life will be saved as the possibility of overcharging and early degradation is ruled out.

On the flip side, modern controllers are blended with advanced features like Maximum Power Point Tracking (MPPT) and smart communication protocols. MPPT technology implies that energy sources are collected as much as possible by changing voltage and current settings dynamically in accordance with real-time conditions such as different solar radiation intensity or load demands. Even so, the controllers offer the possibility to remotely access performance data and make system adjustments by using wireless communication. Consequently, these latest technologies reduce the energy consumed at the sites, bring about a more efficient operation of the systems, and prevent the systems from breaking down sooner, thus giving support in the demand for very sustainable and reliable energy solutions.

Ensuring Long-Term Performance and Reliability

To assure efficient and durable performance of generator parts for a long time, it is imperative to carry out regular maintenance work. This involves regular checks for any signs of wear or tears, on-time changing of filters, greasing of the moving parts, and cleaning so that the debris does not build up. Getting the same service that has been recommended by the manufacturer to be done at the point in time mentioned is crucial to detecting the cause of any possible premature failures.

Perfect storage conditions are also a great factor; generator sets should always be stored in a dry controlled area in order to reduce the risk of corrosion and moisture damage. The quality of the fuel should always be checked, as it is important. The fuel, which is old or contaminated, can be a reason for engine malfunctions, so regular fuel tests and treatments should be carried out. And lastly, running the generator on a regular basis, even during non-emission periods, not only will ensure the functionality of the unit but will also make it ready for use.

Choosing the Right Maintenance Kits

One of the key aspects that helps ensure the top generator performance and the longest possible lifetime is the purchase of an appropriate maintenance kit. Generally, maintenance kits are intended for certain generator models; in that case, checking the make and model of the equipment is a paramount task in the process. It is quite natural that a complete kit would pack along the oil filters, air filters, spark plugs, and also pre-measured engine oil which, of course, will relax the tension of the dedicated technician who is performing the service.

While considering different ways of handling a given situation, the first preference needs to be given to the kits that adhere to the Original Equipment Manufacturer (OEM) standards since these kits are designed to respect the generator’s technical specifications. Moreover, a number of the advanced kits on the market might even come equipped with some new items that are not so common among the others but are very helpful for generator users such as fuel stabilizers or the very best diagnostic tools. The use of kits that contain good quality synthetic oils can also be one of the strategies to get longer life of the generator and wider temperature tolerance.

Important: Ensure, at last, that the maintenance kit is obtained from a highly reliable supplier or directly from the manufacturer to avoid fake parts that could put the generator’s performance or safety at risk. The right kit selection and usage not only adds to the operational efficiency but also minimizes the chances of unexpected failures.

Enhancing Efficiency with Quality Generator Parts

The progress of the generator parts led to the modern era of efficiency and reliability in a very big way. For instance, air filters that are very efficient in design and features nanofiber technology that can trap microscopic contaminants much better. Thus, it reduces engine wear and prolongs the life of the system. In quite the same way, the latest fuel injection system now uses precision engineering methods, which maximizes the combustion process and lowers fuel consumption and emissions.

The significance of using the right kind of lubricants, which are able to withstand heat, was greatly shown through the latest industry figures, especially for generators running in challenging environments. Such ultra-modern lubricants keep their viscosity constant over a wide range of temperatures, thus the most important engine parts are looked after properly while in operation. Moreover, power regulation technology made a step further with the invention of AVR or Automatic Voltage Regulators that include the possibility of smart monitoring, and they are very essential as they make it possible to have the same power output even when the load demands are fluctuating.

Key Takeaway: It is a blend of these most advanced parts that will make generator operation not only the best, but also the most economic, and at the same time, a great contribution to saving nature by being compliant with the environment governing laws. Acquiring the best quality and the most advanced parts is the necessary first step not only to improve the efficiency, but also to secure the power system’s long-term reliability.

Long-Term Care Strategies for Generators

Ensuring the long-term reliability of generators is highly dependent on having a structured and proactive maintenance plan. The inspection should be made a routine one so as to enable the evaluation of critical parts like the fuel system, cooling system, and electrical connections. Follow the manufacturer’s guidelines while making regular oil and filter changes as it will help to avoid the early wearing of the engines and will also ensure the optimum lubrication. Employing the very latest monitoring tools can help a lot in that they offer real-time performance-measuring solutions, e.g., the voltage output, the temperature of the cooling system, and their vibration patterns, which makes a very early identification of the possible issues.

It is very important to do the periodic load bank testing in order to guarantee the reliability of the generator under high-demand conditions. The process makes sure that the engine and alternator can run at full capacity without being taxed too much. It also stops the accumulation of carbon deposits in diesel generators, which then can make efficiency worse after some time. Load bank tests make it possible to put control systems, transfer switches, and circuit breakers under severe tests and verify that everything is operating correctly.

Fuel management is one more important element in the maintenance of the generator for many years. As time goes by, the fuel which is stored, in particular diesel, can deteriorate on account of contamination, oxidation or water presence. This could eventually result in blockages of filters, failures of injectors or lower effectiveness of combustion. Various ways to approach this situation, such as by polishing fuel, separating water, and using stabilizers, can aid in lowering these risks. Nevertheless, checking stored fuel every now and then for contamination and changing the supplies are the ultimate solutions to avoid any interruption in the fuel quality and generator operation during emergencies.

Reference Sources

- “Materials use in electricity generators in wind turbines–state-of-the-art and future specifications”

Read more on ScienceDirect - “Availability assessment of diesel generator system of a Ship: A case study”

Read more on IJPE Online

Frequently Asked Questions (FAQs)

What should I check before ordering generator parts?

How do maintenance kits improve portable generator reliability?

Maintenance kits combine essential parts such as filters, spark plugs, and oil which can be used for routine services and are therefore also recommended to increase the life of the component. It is always the best option to go with high-quality parts that are offered through maintenance kits, as the performance and lifetime benefits are quite noticeable even when we talk about frequently used portable generators. Different kits that are available through dealers providing genuine parts might fit the need to be used with either type of engine. Regular maintenance kit usage is beneficial in terms of eliminating sudden breakdowns and in providing reliable power and service during emergency situations even in times of need.

Where can I find portable generator parts for sale?

You can find portable generator parts being sold through genuine and authorized dealers, the websites of the manufacturer itself as well as the specialized online retailers that offer a wide variety of generator parts. Always be on the lookout for listings hawking generator replacement parts, as well as those that have a selection of models that are wide and the shipping details that include free shipping offers. Go for sellers who offer and are more than happy to support, besides giving a very clear and easily understandable compatibility information based on the serial numbers to be sure of the availability of the parts you require.

How do I choose the right engine parts for my generator?

When choosing engine parts, make sure they are the ones that are appropriate for the make, model, and whether it is air-cooled or not of your generator. Then, do look out for the serial numbers to be an exact match if at all possible so as to ensure a snug fit. Keep yourself open to the possibility of high-quality parts that are being produced by leading brands such as Kohler, Generac, or Cummin as these are the ones that will give you optimal performance together with a long life. And lastly, do not underestimate the power of being helped by the professionals at the store who can advise you on the right parts and make sure they are correctly placed through their installation tips.