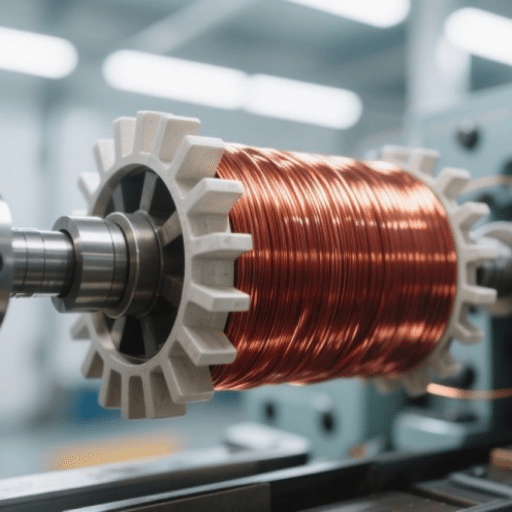

As for the winding material of a generator alternator and the subsequent processes, the type of material used is a major factor that influences the efficiency, durability, and general quality of the generators. The most common materials for this purpose are copper and aluminium. Each of them has its own pluses and minuses. The following brief description is given to provide a detailed comparison of the two metals so that the reader can see the unique properties, applications, and the factors like electrical conductivity, thermal performance, cost, and life in which the two play a role. No matter if you are a professional in the energy field or just a person who is getting more and more interested, this piece of writing will be just the right thing for you and will help you acquire the know-how about the winding material best suited to your individual needs.

Differences Between Copper and Aluminum Windings

- 1

ConductivityCopper has a higher electrical conductivity than aluminum, which, in turn, makes the copper windings transmit electricity with less loss and more efficiently. This eventually results in less energy being wasted and performance being improved.

- 2

DurabilityCopper, with more mechanical strength than aluminum, is, therefore, more durable. It does not wear out, corrode, or expand thermally as fast as aluminum, thus making it an excellent choice for use in places where harsh conditions prevail.

- 3

WeightAluminum is much lighter than copper material, and so it is the better choice for applications requiring a reduction in weight and places that require lower load handling capacities.

- 4

CostAluminum usually comes with a lower price tag than copper does, which means it is an economical option for installation on a large scale or in cases where the budget is very tight.

- 5

ApplicationsThe high efficiency and durability of copper have won it a place in both industrial and high-performance / high-demand areas. Aluminum, although not as efficient, is often used in places like buildings, offices, houses, etc., either for the lighter weight it offers or for its lower price tag as compared to copper.

Physical Properties of Copper and Aluminum

| Property | Copper | Aluminum |

|---|---|---|

| Density | 8.96 g/cm³ | 2.70 g/cm³ |

| Electrical Conductivity | 59.6 x 10⁶ S/m | 36.9 x 10⁶ S/m |

| Thermal Conductivity | 401 W/m·K | 237 W/m·K |

| Melting Point | 1,085°C | 660°C |

| Corrosion Resistance | High resistance to corrosion | Moderate resistance, prone to oxidation |

| Malleability | Highly malleable | Highly malleable |

| Tensile Strength | ~200-400 MPa | ~70-300 MPa |

| Weight | Heavy material | Lightweight material |

| Oxide Layer Formation | Forms a stable, protective patina | Forms aluminum oxide for basic protection |

| Magnetic Properties | Non-magnetic | Non-magnetic |

Conductivity Comparison

It can be said that significant differences exist in terms of thermal and electrical conductivity when comparing the two materials. At the same time, copper has a very high thermal conductivity of about 401 W/m·K, which is almost double the value of aluminum with 237 W/m·K as the measured value. That is why copper is a better material for exchanging heat in applications like heat exchangers and electronic components, where heat dissipation is not only important but also a major issue.

On another note, it has been mentioned that copper outclasses aluminum in terms of electrical conductivity with the former having a conductivity of about 59.6 × 10⁶ S/m and the latter 37.8 × 10⁶ S/m. The very reason the material is termed as highly electrically conductive is the foremost property that has made copper find application in many instances such as high power transmission and distribution, high-performance electrical wiring, and motor windings. Copper, although having a lower density than aluminum, exhibits the same electrical conductivity, so it will also be a good choice in situations, for example, of aircraft and power lines, where lightness is extremely important.

Weight Considerations

When choosing different materials for many engineering purposes, weight is one of the most important aspects to take into account. As for aluminum, its density, approximately 2.7 g/cm³, is much less compared to copper’s 8.96 g/cm³. The difference in the densities makes aluminum a preferred choice in industries such as aerospace and automotive, the reason behind this is that when the overall weight is little the fuel efficiency also gets better and the overall performance is also better. Nonetheless, the lower strength and not-so-high conductivity of aluminum, in contrast with copper, make the use of aluminum not that straightforward. In order to deal with this, for example, in overhead power lines, the aluminum is frequently reinforced with a steel core, which helps it to keep its lightweight feature while its structural integrity is maintained. The development of material science has given birth to a new world of possibilities where the extent of weight reduction and performance level optimization has been made flexible.

Cost Considerations in Generator Windings

The cost of generator windings is an aspect that depends heavily on the material used. Copper is a more costly alternative to aluminum, but it offers better electrical conductivity and durability, which therefore allows for less power consumption and a longer life expectancy. Consequently, aluminum windings have the advantage of their low price and lesser weight and, therefore, are also less expensive during the operational phase. Nevertheless, this material choice conversation reduces to the question of where the economy lies between initial and operating costs, that is, a question of balanced costs. Copper, speaking of a higher initial cost, if the subject is of many applications, it is still the preferred choice for the benefits of reliability and efficiency.

Price Differences Between Copper and Aluminum

The substantial price difference between copper and aluminum is evident and attributed to the discrepancies in material costs, production methods, and supply. Recently released market figures show that copper has the habit of being much more expensive than aluminum, with the gap widening so much that it sometimes equals the copper price being three to four times larger per pound than the aluminum price, depending on the state of the market. The main reason for this is copper being much superior in terms of conduction, durability, and the laboriousness of its extraction which all form part of the high production costs that copper has to bear. On the other hand, aluminum is abundant and less costly to both obtain and treat, so it emerges as a cheaper alternative.

Nevertheless, lower quantities of money needed for aluminum at the start may still be the best up-front saving. Cost-efficient aluminum for first-time installation is still being used – but such issues as greater resistance (and thus energy losses in some cases), as well as maintenance requirements, could counterbalance the price advantage in the long run. The best economic choice can be found only by thoroughly considering the price-performance ratio, depending on the application and operational lifecycle.

Long-term Value Analysis

Copper windings are able to lead to better thermal performance and durability, among others, when compared with the aluminum ones due to their superior thermal conductivity, which is around 60% higher than that of aluminum. This very feature lets the copper windings operate under a greater range of current densities and, at the same time, dissipate heat much better. As a result, devices equipped with copper windings are usually subjected to less thermal stress and, thus, the risk of premature insulation wear is minimized, which leads to the prolongation of the equipment’s operational life.

Aluminium, although less thermally efficient, is lighter and this could be very beneficial in applications with weight constraints as a major factor. However, the increased thermal resistance of aluminum windings can have the edge of achieving higher operating temperatures under equivalent load conditions, which explains the need for more powerful cooling mechanisms or derating in order to secure the reliable performance for long periods. The overall decision between these two materials also needs to take into consideration the particular requirements for heat dissipation and durability of the specific application.

In comparison to aluminum, copper windings are more resistant to environmental influences like oxidation and corrosion, from a maintenance point of view. Aluminum needs to be treated with special gear or coatings to take care of these problems since the material is very sensitive to the above-mentioned factors; consequently, maintenance requirements can go up, and the cost of life cycle maintenance will also be higher. Copper being stronger mechanically also entails better long-term reliability, besides, thus minimizing the risk of machine changes and connection errors owing to the mechanical or thermal stress factors.

Maintenance Expenses Comparison

Very often, when the maintenance expenses are being evaluated, we can conclude that copper windings are lower in the total costs because of their hardness and reduced wearability during the functioning stress conditions and operations. With copper’s resistance to thermal expansion, we can expect connections to remain stable and not grow loose over time, so that they infrequently start to become a problem and thus a need for maintenance checkups. Besides that, the lower resistivity of copper cuts down the heat generation during the operation process, hence insulating materials will last and the equipment’s lifespan will reach the full period.

On the other hand, aluminum coils usually come with higher servicing requirements because they expand easily due to heat and are weaker. The heat expansion and the tensile strength make the joint more susceptible to loosening, oxidation, and the formation of other structural problems even under normal conditions, which, accordingly, will require continuous checking and even repairing. Besides reaching fully satisfactory usage conditions, aluminum parts are often subject to more thorough design criteria, like the need for larger ones or the use of special clamping systems, which in turn leads to more maintenance-related difficulties and expenses.

Relatively more to the point, data on the operation and maintenance of the two types of motors show that the cost savings obtained from having copper windings as a major part of the motor construction are substantial compared to the relatively small increase in the cost of the original supply when spread over the life of the machine. This confirms the trend for copper usage in cases where the major concerns are maintaining a high reliability factor, achieving good long-term performance, and low-cost maintenance.

Performance Comparisons in Generators

Aluminum windings are less electrically conductive than copper, resulting in generators with lower efficiency due to power losses. This inefficiency factor goes down with the use of high-capacity generators, where the performance is a critical factor. In addition, the strength of copper being higher than that of aluminum makes it more durable and less subject to mechanical and thermal stresses, which would have spoiled the reliability. Nevertheless, Aluminum windings still have the advantage of being a lighter and less expensive alternative, even though in the long run, they may wear out more quickly because of the expansion and contraction caused by the fluctuation of the temperatures. Given the fact that the most important characteristics of the windings are reliability, efficiency, and long life, copper windings, in the majority of cases, are the winners in the performance evaluations conducted.

Power Output Evaluation

In comparing the ability of power output, copper windings show better conductivity related to their electric power, which in turn leads to less resistive losses in energy transmission. The approximate electrical conductivities of copper and aluminum are 59.6 × 10⁶ S/m and 37.8 × 10⁶ S/m, respectively. The exceptional feature of the former makes it a better candidate for high current operations since hot spots are not produced as a consequence, and the system runs more efficiently even in high-peak load cases.

On the other hand, aluminum windings, although being of less weight and cost, need a large cross-sectional area to obtain an equivalent copper conductivity. Such an increase in size can be a drawback for the formation of compact designs in electrical systems, especially when power density is targeted. Moreover, the higher energy loss in aluminum can result in higher energy consumption and less efficiency overall, especially in applications requiring high and sustained power output.

Many times, the usefulness of copper outweighs aluminum’s cost and weight advantages in the applications where electrical conductivity and energy efficiency are of utmost importance such as in the power transformers, industrial motors, and high-capacity generators. Thus, with aluminum windings being a feasible low-cost solution for the easygoing uses, it is still copper that leads the way to the best output and operational dependability in the industry and hence is the more expensive choice.

Energy Efficiency Under Load

There is a clear efficiency and thermal performance superiority of copper over aluminum when windings are compared under the conditions of load. Indeed, the resistivity of copper is at least 1.68 µΩ·cm, and its ability to conduct electricity with minimum energy loss largely accounts for its reduced resistive losses. This means that power consumption is more efficient, especially at high loads, where considerable heat is produced by the flow of electrical charge. The conductive property of copper is so good that it has the ability to lower the voltage drop and wastage of energy, and therefore, it is most appropriate for the high-power systems in which continuous operation is to be guaranteed.

Unlike copper, aluminium, the banana of the conductors, but with a resistivity of about 2.82 µΩ·cm, needs thicker wires to carry the same amount of electrical current. This, in turn, makes the system that uses it economically more bulky and thus more complex due to heat removal and mechanical stability issues. On the other hand, one must be careful, as with continuous use, saturation of the heat absorption capability and oxide formation are the main causes of the electrical losses, resulting in high operating temperatures and possible connection quality degradation.

Industry studies point out that, despite the lower cost of aluminum, the lifetime energy losses attributed to the higher resistivity and thermal limitations of aluminum frequently surpass the initial cost savings. Critical applications, such as high-capacity transformers and industrial machinery, copper’s optimal mix of conductivity, life expectancy, and thermal robustness means that it is still the best choice for materials that contribute to energy-efficient heavy electric load operation.

Durability of Copper vs Aluminum Windings

Due to the fact that copper windings are more durable than aluminum windings on the grounds that they are more mechanically strong and have better resistance to fatigue, it is an almost worldwide belief . Thanks to the great tensile strength of copper, it can easily cope with a much higher physical pressure, such as vibrations and thermal expansion, all without deformation or breakage. Moreover, next to aluminum, copper has a lower tendency to oxidize, which, in turn, is a better maintainer of the material’s conductivity and strength through time. Although aluminum windings could be a lighter and more economical construction, still the higher strength coefficient of copper and its less likely to be oxidized feature make it a better choice regarding the longevity of material; this is the reason why copper still has the leading position in the electric wiring industry in spite of being higher priced.

Resistance to Wear and Tear

Copper windings typically have very high resistance to mechanical wear and fatigue, which is directly attributed to their higher strength and better ductility. This attribute of copper lets it withstand the high stresses of operations like those due to vibration and the heat-expansion-contraction cycle. Besides, the inherent hardness of copper not only gives it a lower susceptibility to superficial abrasion but also guarantees a longer life span in the case of harsh mechanical or environmental strains.

In contrast, though they weigh less and are more economical, aluminum is the material used for windings with the weakest wear and tear properties, as it has a softer structure. This weak spot in the material increases the chances of the surface becoming worse with time, mainly when it is in contact with very few mechanical vibrations or extreme physical impacts. The thermal expansion coefficient of aluminum is also relatively high, which, in connection points, can result in a higher risk of getting disconnected, thus leading to quicker wear of the product. These issues render aluminum unsuitable for environments that require the highest resistance to corrosion and constant reliability; in cases like these, copper is still considered the best material.

Some numbers, collected by means of industry-wide tests, are presented to support the claim, showing that copper windings are more prone to suffering from performance drops over the years of application way more slowly than the rest in the same level of severity, which is indeed a very practical advantage in the case of very critical and super-demanding situations.

Corrosion Resistance

Evaluating the corrosion resistance of copper and aluminum windings, it is clear that the material’s inherent properties are very important for deciding on the performance and service life of the windings in different environmental conditions. Copper, a metal known for its good resistance to oxidation and corrosion, steadily develops a very thin and protective oxide layer on its surface, thus saving the metal from deleterious oxidizing. This quality of copper windings rather specifically fits them to be used in high-humidity environments or wherever the application is expected to be under the effect of corrosive agents such as salt or industrial pollutants.

That being said, aluminum is more vulnerable to corrosion, mainly because it tends to create a less stable oxide layer and thus a protective one when it is in an active environment. Nevertheless, the metal still achieves a certain corrosion resistance level as a result of the oxide layer; however, at the same time, it is also weakening its structure due to the cracks that are created when the layer is under mechanical stress, and through these cracks, the metal is exposed to further corrosion. The combination of aluminum with the dissimilar metal in the presence of an electrolyte can also bring about galvanic corrosion, which, in turn, reduces the overall mechanical stability of aluminum.

The recent developments in the material coatings and alloy compositions have focused on reducing the limitations in aluminum winding. Still, the cost increase and the issues with complexity meet the methods of the copper wire, which are becoming the main available option for harsh environments and other cases of long-term reliability. The experimental results in the case of environmental conditions still show the copper to be superior to the aluminum in terms of electrical and flexibility, even in the case of identical stress and test conditions and over a significantly longer time; hence, copper is considered the best material for critical electrical winding applications.

Choosing the Right Material for Specific Use Cases

The difference in copper or aluminum windings is made according to the application’s special demands:

- High Efficiency and Longevity:

Transformers and heavy-duty motors are the most likely to benefit from copper windings. High voltage and resistance to mechanical wear are two important properties of copper. Its heat resistance makes it an even better option for tough applications.

- Cost-Sensitive Applications:

When cost is at the top of the priority list, aluminum windings turn out to be the best economical option. They find wide use in household transformers and a variety of other areas where the weight and the amount of spending are the critical points.

- Weight Considerations:

Moving up and down in weight, the lighter side of aluminum is a strong motivation for such industries as aerospace and makers of portable electrical devices, where the whole system’s weight has to be critically cut down.

- Specific Environmental Factors:

If the conditions under which the circuit is working are such that high humidity or exposure to corrosive agents are present, copper is probably the better choice. This is because of the superior resistance of copper to corrosion, which is achieved when it is properly insulated.

An assessment of the above factors—efficiency, cost, weight, and environment—enables the engineers to opt for the most appropriate material according to the use case, whereby the performance and reliability will then meet the operational needs.

High-Performance Generators

Comparing the performance of high-performance generators having copper as the winding material versus those having aluminum as the winding material, the evaluation must take into account the most significant performance parameters, which are electrical conductivity, heat removal capacity, and mechanical durability.

- Electrical Conductivity:

Under normal circumstances, copper has a much higher electrical conductivity compared to aluminum, approximately 60%. This quality of copper windings to achieve lower electrical loss is greatly required, especially in high-performance applications where efficiency is directly proportional to the rate of output and the operational costs.

- Thermal Efficiency:

One of the most significant factors affecting generator performance is proper and effective thermal management. Copper has the highest thermal conductivity among all the different metals that exist in the universe and that gives it the ability to take the heat away more efficiently. This, in turn, is helpful in reducing the possibility of overheating and thus extends the lifespan of generator parts, hence the need for less maintenance.

- Mechanical Strength:

Physically, copper whirls have better tensile strength and fatigue resistance, which makes them suitable for moving applications. The Aluminum one is lighter; however, its Young’s modulus is not sufficient to secure its application for a longer time.

- Cost Considerations:

Normally, it is easier to take a low-priced aluminum one instead of copper. Material availability and the less dense properties are among other reasons why aluminum is considered a more economical choice over copper. Yet, with copper, one can recover the initial cost of the generator by saving on operational costs and increasing service life durability.

Cost-Effective Solutions

The comparison of copper and aluminum, for electrical generator windings, turns to be a question of pricing, performance and long-term prospects. Aluminum, with its light weight and convoluted economic situation, can lower costs effectively; that is why it is the material of choice for applications with stringent cost limitations. Unlike copper, aluminum, and electricity, electronics applications in general are more interdependent. Industrial buildings and their integration within cities; power generation plants and the installation of their power lines; renewable electrical solar panels and the conversion of light to power through them, are sources, sources, and storage, respectively.

Contrary to that, in terms of being costlier upfront, copper windings let heat and electricity pass better and are almost unbreakable. That is why the machine or system consumes less power and very little maintenance might also be needed, thus not only lowering but two in all at once—the efficiency of the unit, especially in high-performance execution. Moreover, the copper’s greater heat resistance and protection against rusting are the other two factors that result in the shortening of the average service life of the product.

Besides, to get better results, the manufacturers have been introduced to new and modern methods of winding using a mix of the two materials or winding with expertise through optimally geometrically shaped windings. Considering various aspects such as the function, place, and cost factor of a new system in the evaluation process can avert potential risks.

Reference Sources

Frequently Asked Questions (FAQs)

Is copper or aluminum better for generator winding conductivity?

The electrical conductivity of copper is higher in comparison to aluminum; this implies less resistive power losses and hence, the generator windings will be more efficient. Use of aluminum conductor is still valid if its size is increased to make up for the lower conductivity but this will make the whole apparatus heavy and bulky. Whenever maximum efficiency and the smallest possible winding size are of importance, the use of copper is typically the case.

How does weight affect the choice between copper and aluminum generator winding?

Aluminium is notably lighter than copper, which can be seen as a positive factor when the reduction of the space that is taken up by an object is necessary, e.g., in terms of a mobile or airborne powered by a generator. The choice of aluminium can lead to lower structural requirements and hence lower shipping costs, but on the other hand, larger cross-sections are required in order to achieve the same electrical conductivity as that of copper. Designers should consequently always consider the weight saving offer against the risk of the space being insufficient and the mechanical considerations.

Which material is more cost-effective for generator winding?

Aluminum usually comes with a smaller material cost per kilogram than copper, therefore, it is more attractive to projects with tight budgets. Still, the cost of aluminum system, considering insulation and housing, becomes competitive with that of copper. Moreover, differences in efficiency and potential maintenance in the long run represent the overall cost analysis of the system.

Are there differences in durability and corrosion resistance between copper and aluminum windings?

In most cases copper has a higher corrosion resistance and mechanical strength than aluminum. Aluminum may easily get oxidized and corroded fast at points. To prevent aluminum from corroding proper soldering, the use of coatings, and the required matched connectors can be applied. However, maintenance might become more problematic. For situations where environmental conditions are severe and long-term usage is expected to take place, copper usually appears to be the better choice.