One of the top diesel generators to choose from is either Perkins or Cummins. While both companies provide highly reliable and innovative products, it would not be easy to opt for either of them. Given the fact that the two brands are reputable, their selection is important for both commercial and personal users. Therefore, this paper will also compare other aspects similar to the purchase of a perkins vs cummins diesel generator. We aim to help you understand which set of a gentleman is most suited for what purpose, ‘industrial, back-up power, farflung regions’, and so much so, why. So, stay with us as both of them offer advantages and special features that will be understood based on what the users can easily gather.

Introduction to Diesel Generators

Generators. reliablehelp in converting diesel into an electric current through an engine that is powered by diesel and an alternator. They are appreciated due to their performance, yet widely used in so many cases, such as the provision of power when there is no electricity, the production industry, powering of equipment in remote outstations, etc. Generators that use diesel are known to be highly effective and also last longer than the others. One might go for this size of generators because they can easily accommodate heavy loads. It is these factors that make them instrumental in regard to the supply of stability, even in cases of emergencies.

What is a Diesel Generator?

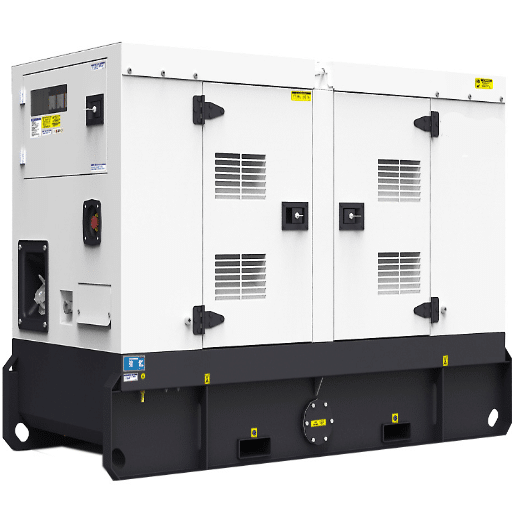

A diesel generator is an apparatus that is used to transform chemical energy available in diesel fuel into electrical energy using a diesel engine and a generator. These consist of a diesel engine, which combusts diesel to generate mechanical energy, and an alternator, which is used to produce electricity. Diesel generating sets are appreciated for their cost-effectiveness and robustness for long durations of operations, thus making them ideal also as backup power generators, and heavy industrial equipment where the power grid is nonexistent. They have a large spectrum of sizes and capacities, starting from small household generators to high-powered heavy-duty units for commerce and industries. Current designs of diesel generators allow the integration of technology for purposes of noise abatement, emission reductions, and fuel economy, among others.

Importance of Diesel Generators

It is absolutely true to say that diesel generators are much needed power supply that cannot be replaced in areas where there is no or very little access to electricity. They are suited to Healthcare, data centers, construction, manufacturing, and such other industries where alternative sources of energy come up short in meeting the demand for round the clock power supply. It can’t be said enough times that comparable versatility isn’t found in any power source other than these, since they are formulated to run for long without major servicing, which provides enough energy to stand in during blackouts or numerous catastrophes.

Contemporary diesel generators are likewise developed taking into consideration rigid environmental regulations. They are built with a modified fuel injection system, control technology, and operational comfort. The low investment cost of these generators is of fundamental relevance in contrast to the costs of the present generating equipment; this is due to the low fuel costs of these generators and the increasing lifespan. This is why, even in the developed countries, for the main energy supply or just in case, diesel generators seem to be impossible to neglect, because of how power supplied virtually all aspects of life has also left critical infrastructures quite vulnerable if power is lost for any reason.

Common Applications of Diesel Generators

Rudiments of Diesel Generator and Its Applications

Diesel generators are very common across numerous industrial sectors, with different aspects of diesel generating sets assuring their significance, efficiency, and usefulness in different ways. In the following section, you will find some of the very basic forms in which diesel generators find their use:

Back Up Electricity

Diesel generators provide a perfect power backup for important public sectors such as hospitals and banks within data centers, and fire stations, among others. They are quick to start and very reliable, thus providing the ability to provide continuous operations in case of a blackout.

Construction Sites

Working at construction sites and areas that are far from the electric grid requires solutions such as diesel generators, which help in the operation of equipment as well as lighting structures all around. The conditions around these devices are so harsh since they are proving to be the best generators to be used on sites with extreme operating conditions.

Manufacturing Systems

Electronic appliances and lights are utilized even where there is a power outage because many industries have diesel-powered generators that put that into action. Furthermore, these engines are used to facilitate heavy machines, especially in oil and gas, mining, manufacturing, and some other industries.

Farming and Water Systems

Traditionally, farmers deploy diesel generators to pump irrigation water, grain elevators, and other types of machinery used in agriculture, especially when the electrical infrastructure is not reliable.

Events and Cinematography

In order to cover this gap and provide electricity for mobilization and incumbent schedule, communication, and a full range of activities at any location removed from the grid, the decision is made to use a diesel generator as a temporary power source for events such as shows and concerts, and film and TV production.

They are highly versatile, such that the use of diesel generators in pre-planned as well as in rescue for specific activities in all parts of the world constitutes an essential element.

Overview of Perkins and Cummins Generators

Diesel generator companies, including Perkins and Cummins, are some of the best-known in the market due to their products’ efficiency and effectiveness in performing the required tasks.

Perkins Generators

Perkins generators are well-regarded because they consume less fuel and are built to last. They are particularly useful in industries where power supply is needed round the clock, without interruptions, like farming, construction, or manufacturing. Combined with the fact that the engines provide a great deal of power with very little maintenance needed, the engines are, in the long run, very cheap to operate.

Cummins Generators

Cummins generators are praised for their capabilities, having power, durability, and the latest technological advancements that these machines incorporate. They are made available for all stipulations wherever both primary and standby power solutions are applied, such as medical centres, techno poles, hospitals, and other facilities as necessary. Mechanically more reliable than Perkins units, these Mediev AL4–L9 systems are built for Peak Performance in demanding as well as extremely adverse environments.

When buying a Perkins vs Cummins diesel generator, everything depends on the scope of application of the machinery.

As both brands have built their reputations on reliable energy solutions and can satisfy the scalability demands of even the most tech-savvy industries, it comes as no surprise that they are both top performers in this generator category.

History and Reputation of Perkins

Perkins Engines was founded in 1932 by Frank Perkins and Charles Chapman in the city of Peterborough in England, and today, the company is known globally as a producer of the best gas and diesel engines. Perkins, a leader in engine design, was at the center of the introduction of innovative ways of using diesel engines in agricultural, construction, and many other applications.

The company is presently a wholly owned subsidiary of Caterpillar Inc., providing access to a robust distribution network worldwide and a wealth of technology. Its excellence in engineering ensures customer satisfaction, with engines that are built to last, consume less fuel, and produce anywhere between five to over two thousand six hundred horsepower. Its brand is synonymous with quality and cutting-edge. Perkins vs Cummins diesel generator – This has integrated itself across all OEM regions across the world and customised itself accordingly to each industry. Its focus on the customer and adherence to high quality have helped it remain a leading supplier of power equipment.

History and Reputation of Cummins

Cummins Inc. is an international company established in 1919 and has its headquarters in Columbus, Indiana, where it is a major player in the power technology sector, especially the creation, production, and sales of diesel and alternative engines, as well as the powertrains containing filters, compressors, and emissions control technologies. The organization was an early entrant who pioneered bona fide diesel engine designs that were reliable and could fit various applications, like heavy-duty trucks, among others. Since its inception up to today, Cummins has placed sustainability at the core of its operations and hence enabled the application of innovative measures toward emission reduction and a heightened rate of fuel consumption. The strategic network of more than hundreds of service centers with its 10 decades of focus on customer satisfaction and product services has enabled the firm to cushion itself in more than 10 industries (the automobile, motorcycle, marine, power generation, aviation industry), just to mention a few. However, the advantages of these two engines could also be disputed on perkins vs Cummins diesel generator. As well as many other people argue when comparing these two.

Market Position of Perkins vs Cummins

Both Perkins and Cummins engines are produced by famous companies with a long history of successful operation in different markets and with specific strengths. Popular for making small and medium-duty engines, Perkins mainly focuses on agricultural, construction, and power-generating engines. Their products are known for their durability, simplicity, and serviceability, making their engines popular with original equipment manufacturers operating in compact equipment markets.

The two compared companies are in different parts of the market, and the difference is roughly that Cummins is in the high-power diesel engines in all sectors, whereas Perkins is in the low-power units used in the automotive sector. As the contrasting case shows, the three positions are veiled innovations, and Cummins developed a keen emission injunction system and alternative fuels technologies. This helped them come out as active while respecting the environment, meeting harsh environmental regulatory requirements. In dealing with this, Cummins’s range of services, from a global and strong service network, makes it the last stop for high-durability, well-performing engine customers.

To sum up, Perkins reaches out into the sectors that require low-cost, simple, and trustworthy engines, whereas Cummins understands the need in other markets and penetrates them with its more advanced and large-scale technologies.

Detailed Comparison of Perkins and Cummins Generators

Functionality and Productivity Considerations

Perkins generator sets have a proven track record for fuel economy and performance, particularly when it comes to limited scopes of work, such as for standby power in homes and small businesses. The machine’s engines are constructed to work efficiently within a certain load-selection justified by performance, thereby eliminating the need to increase operating costs. Whereas the Cummins generators are effectively built for use in a more demanding, industrial scale. They have powerful systems that maximize combustion and other technologies for boosting power, managing emissions, and operating under different levels of load.

Technologically Related Attributes

Whereas Perkins handles its offerings in new ways to compromise user friendliness without excessive maintenance and overly complicated control systems, Cummins leads the market with new concepts of smart technologies and does not hesitate to use sophisticated electronic control panels, space handy monitoring, and state-of-the-art maintenance diagnosis features. Cummins wins in contemporary complex and highly commercial and industrial applications, which involve power/demand variations mainly because of these technical improvements.

Durability and Reliability

Both Perkins and Cummins excel in issues of durability. Even the warranty given on Perkins generators is indicative of their robustness, since they can last for long hours of use, provided the user keeps up with the recommended maintenance. Cummins generators seem to exceed those great expectations of wear and tear and perform in the hostile environment, and even higher as well. This is due to the very heavyweight parts and trends of material and the systems fitted in them, which help withstand extremes such as mining and construction sites.

Market Reach and Support

When it comes to the provision of mechanical equipment, peripheral to car engines, the Perikonesas and Mannes, Perkins takes the first place or first quintile. Perkins outperforms Cummins in two ways: price and service coverage, especially in regional and local markets. The large-scale multinational penetration and reach of Cummins, with state-of-the-art facilities and services to match every need, positions them at the top in cases of large mission-critical installations, where parts or a technician must be in place in an instant. Due to this, Cummins is likely to be favored by the clients who demand constant performance and proper assistance on every continent.

Performance and Power Output

With high power capacity as guaranteed by the type of engine used by most of their models, Cummins engines have grown to be renowned worldwide as the best engines out there and one of the most efficient at that. Each engine by Cummins is perfectly engineered such that it gives maximum torque even at low RPM. Power production is not only high but also easy, and less fuel is also burned. Latest Cummins engines make use of the latest advanced technologies, such as VGT turbos and the HP-Isys, to provide high performance with a low weight. They are also used in relation to exhaust emissions control, stressing compliance with the level of pollutants such as the Tier 4 and Euro standards 6. Gerotor pumps in Cummins engines ensure that the engine is as efficient as possible, providing the greatest services and giving reliability when they are pushed to the limits.

Fuel Efficiency of Perkins vs Cummins

Juxtaposing the fuel-efficiency of Perkins against that of Cummins motors, it quickly becomes evident that both companies seek to achieve the same goal- reduce fuel use and utilize the engines for their maximum potential at decreased fuel consumption. Such an establishment by Perkins Motors facilitates the use of the engines in such applications as those based on agricultural and construction equipment, which require specific fuel consumption rates and constant operation. The focus here is efficiency in a medium-powered engine where the efficiency should not be compromised by low speeds.

The engines made by Cummins are built with more advanced technologies like high-pressure injection or an electronic system that helps to optimize the fuel consumption, especially when the engine has to push at the top of its capacity. Such is possible because, after many years of research, efficient technology has been embedded in the Cummins engines, thereby providing savings in fuel usage in prolonged and tough duties.

In the end, the decision mostly stems from the usage purpose one has of the respective engines. Most of the time, for mid-range performance, Perkins engines often win out, while for high-output engines, there is more economy achieved by Cummins.

Reliability and Maintenance Considerations

Regarding the issue of the reliability of an engine for a commercial purpose, Perkins engine models have remained on top for high-workload applications in harsh environments. This is due to simplicity in the engine design, which aids in the operation of the engine for a longer period with minimal complications.

Metal stems on engines employed in industrial operations are also more robust for long-distance driving, say, a Cummins engine. This is attributed to a unique series of engine and heavy component designs that saved the company’s credibility in many parts of the world because of the Perkins vs Cummins diesel generator.

It is also important to consider that when it comes to maintaining the equipment, Perkins, unlike its competitors, is easily maintainable through the availability of spare parts, which are everywhere and designed for a very simple form of maintenance to the extent that conducting repairs is relatively inexpensive. In contrast to Perkins, Cummins engines require more skill in use since they are technologically advanced, yet such developments are backed by a rich network of global support, including spare parts and service personnel. Without a preventive maintenance program, the operation, fuel consumption, and engine life in both cases will be less, allowing proper maintenance and more effectively followed to avoid any distress of a Perkins vs Cummins diesel generator niba rwogweta.

Choosing Between Perkins vs Cummins

Diesel generator types include standby, prime, and continuous, with options available for Perkins and Cummins across these categories.

| Key Point | Perkins | Cummins |

|---|---|---|

| Power Range | Wide range, up to 2500 kVA | Broad range, up to 3750 kVA |

| Durability | Proven longevity, robust design | Exceptional under extreme conditions |

| Fuel Eff. | High, designed for lower fuel consumption | Optimized for cost-efficient operations |

| Noise Level | Generally quieter | Includes models with superior noise reduction |

| Aux. Parts | Excellent global availability | Extensive, well-networked global availability |

| Maintenance | Simpler, typically lower cost | Reliable, with slightly higher service cost |

| Warranty | Comprehensive options globally | Industry-leading, premium support packages |

| Tech Level | Advanced, with smart systems compatibility | Cutting-edge, IoT-enabled modern technologies |

This brief comparison indicates that Perkins and Cummins Diesel generators are both efficient and dependable power solutions for many applications. However, when Perkins vs Cummins Diesel generator is considered, the latter one is quite powerful due to larger capacities and advanced technology, while the former is sturdy, fuel-conserving, and straightforward in terms of repair. Mostly, these two power units should be chosen depending on the application of the consumer where the generator is to be used, and their financial implications.

Assessing Your Power Needs

Prior to choosing a generator that meets your needs and requirements, you should first ascertain the amount of power you require. This means capturing the quantities of all the systems and appliances that will be backed up by the respective generator and then summing up their power. Take the time to determine the wattage required to run the devices and the pressure as well for those bits of equipment that have compressors or motors, for instance. Next, the usage and indeed the kind of exploitation is to be analysed, related to closed or open premises, operating temperatures, and probably even restrictions on the noise levels. It is also necessary to pay attention to fuel supply and its economy to avoid the stoppage of the equipment from running due to the costs involved. Whether it be Perkins vs Cummins diesel generator or features such as remote monitoring, which may help reduce operating expenses or even paralleling the generators, these should also be considered. Finally, it is essential to incorporate maintenance intervals in your planning, including overhaul intervals, for constant uptime and availability in the field.

Parts Availability and Support

When examining the issue of parts availability and support of equipment, it is pertinent to take into account the market reach of the manufacturer as well as the presence of authorized dealers or service centers. Most industry specialists have a wide range of commonly requested parts easily available in stock that helps in situations where repairs are to be conducted within the shortest time possible. Furthermore, it is worth noting that some brands from which one should expect detailed information, such as manuals and parts illustrations, as well as customer service, include phone and or web-based technical assistance. Where applicable, one may also find provisions for faster delivery of crucial parts and or regular maintenance, where the plans are paid on a subscription basis, which increases the reliability levels. To avoid the risk of equipment failure and inefficient use of resources during the equipment service lifespan, it should be rebuilt, regardless of whether the distributor has a strong supply system as well as good customer service capabilities.

Long-Term Cost Considerations

An in-depth analysis of the cost of equipment in the long run is critical, as it helps minimize the costs of equipment use in a given period. To begin with, the purchase cost is not the only concern, but the carrying costs, which include expenses of the equipment for maintenance, repairs, energy, and also spares during the time of use when the equipment is being utilized. This is referred to as the total cost of ownership (TCO). The use of energy-saving machines reduces the power bills after a few years, while there is also the presence of maintenance-free as well as cheap spare equipment. The user of this coverage and the cost of warranty are significant in most health plans, as either service contract enables the prediction of some of the costs in advance, hence helps to relieve the pressure of repairs and the extra costs associated with them. It can be noted that generation from internal combustion engines can utilize more than one type of fuel, for instance, Perkins vs Cummins diesel generator.

In addition to the costs of monetary losses associated with operational disruptions, enlarged intervals between maintenance may result in hidden costs, and therefore, the loss reduction improves when reliability measures and preventive maintenance are implemented. At the onset, it may seem costlier to use solid equipment of good quality, but this saves money because the equipment lasts longer and better. Also, the disposal value needs to be checked to calculate whether the rest of the equipment that has a sufficiently high second-hand value can be counted against the implementation costs. Businesses can thus find the cheapest options without compromising operational procedures and sustainability by evaluating all these aspects step by step.

Features of Perkins and Cummins Diesel Engines

Perkins Diesel Engine’s features

- The economy of Fuel: The design of Perkins engines focuses on the efficiency of fuel utilization, which in turn allows for reduced and economic exploitation of the engines for long.

- Support: Perkins engines are well known for their superior endurance capacity and provide impeccable thrust in any adverse conditions.

- Multiple Uses: Most of Planter’s engines can be used in Beyond the farm, and also for construction and electricity in almost all places.

- Facilitated design: Maintenance of the Perkins engine is very easy, as it is designed in such a way that downtime and service expenses are minimized.

Cummins Diesel Engine Features

- Enhanced Power Performance: One of the most distinct characteristics of Cummins engines is their enormous amount of horsepower and torque, which makes them particularly useful across all robust industries.

- High-End Technology: Also allows the use of advanced emission, sound, and performance systems.

- International Presence: Assistance in every region and parts available in all countries to avoid any interruptions.

- Flexibility: Many areas employ Cummins engines, such as transport, marine, or industrial equipment.

Innovations in Perkins Diesel Engines

Numerous current diesel generators used in industrial applications are powers who are renowned for their outstanding performance in science and spirit in shaping better engines for the users, and among the most popular manufacturers of these generators is Perkins. As the number of plants with diesel generators increases, the following changes have been incorporated:

Controlling Emissions and Meeting the Requirements:

Perkins made an effort by creating engines that conform to current global emission controls, including Stage V and Tier 4 Final, without sacrifice of either power or efficiency. The examples are cleaner engines due to cleaner emissions without a sacrifice of relevant power production.

Declining fuel consumption:

Given the expectations on power needs of particular consumers with state-of-the-art electronic control units (ECUs), accompanied by sophisticated spare parts from the engine, Perkins engines pass the test of optimal fuel utilization. This, in turn, cuts down the fuel expenses and helps give protection to the environment as well.

Compactness and modularity in design:

Perkins has come up with engines that are compact, modular, and easy to fit into many machines. These designs also reduce service time and, in general, cause less nuisance.

Smart engines:

Perkins has installations of cutting-edge telematic solutions for their engines, such as the Perkins® SmartCap and its accompanying application. Such solutions offer engine-in-use monitoring capabilities, hence enabling preventive maintenance, and downtime is reduced.

Unique Features of Cummins Diesel Engines

Perkins vs Cummins diesel generator debate is popular due to their distinguishing characteristics as far as engines are concerned. In the Cummins case, they have a very complex fuel injection mechanism such that there is maximum power with minimal consumption under various conditions. Furthermore, these engines also have robust components that have been extensively tested over the years; as a consequence of this, they are quite reliable. Contemporary emission reduction methods, which are incorporated in their design, are within the limits of any conventional jurisdiction and are safe for the environment. Additionally, Cummins incorporated systems that diagnose and provide support in an effective way, reducing the need for costly repairs and keeping downtimes to a minimum in critical systems. It is for this combination of efficacy, environmental friendliness, and backup that distinguishes Cummins from the rest in the diesel engines sector.

Comparative Analysis of Features

In the context of comparing diesel engine producers, Cummins deserves to be singled out because it constantly pays attention to durability, creativity, and eco-friendliness. SCR and EGR emission control technologies are incorporated into Cummins engines in order to optimize their environmental performance in view of the toughest emission requirements in the world, which are Euro VI and Tier 4. These technologies provide a more effective reduction of CO2 and consumption of fuel at the same time, unlike many technologies provided by others.

Apart from that, modular designs of engines are also a strength of Cummins that enables the design and manufacture of different products ranging from heavy-duty vehicles to marine engines. While many brands with this limitation fail in this regard, Cummins systems can be expanded and/or transformed to meet different operational backdrops effectively. Forward-looking investments in hybrid power sources and alternative fuels further boost the company’s leadership position in sustainable technology, thereby proving its adaptability.

Another distinctive aspect of Cummins is the provision of extensive service and support infrastructure. The organization has a wide array of service centers spread all over the world as well as advanced digital diagnostic tools, which enhance the ease with which maintenance and repair services are offered. This approach to support, unlike its competitors, which tend to use a separate system, renders a much more efficient model that utilizes the availability of Cummins’ services through a higher number of users, with reduced downtime and reduced lifetime expenditure on users.

Reference Sources

Part-load economy of diesel-electric generators

Read the study

Generator selection problem using MOORA and TOPSIS methods

Read the paper

Frequently Asked Questions (FAQs)

Perkins vs Cummins: Which one is a better generator for heavy-duty engines?

People mainly select either Perkins or Cummins, depending on the reason behind desiring a heavyweight engine for a certain application. Cummins engines are known for their high power capacity and torque, and are often utilized in rough terrains where there is a need for continuous power with minimal fuel emission. Perkins, on the other hand, is a dominant player when it comes to designing some of the most reliable diesel generating sets that can be used in different applications, for instance, which will be where minimal noise will be required at the same time, the design will be made very compact. The two companies mentioned above are also rich in terms of ensuring that they meet the expectations of the consumers when it comes to delivering quality diesel-driven machines and this is why they suggest that aside from minimizing the cost of energy, one has to make sure the clustering of the machines is proper and the machines are covered especially with filing and stones, and under leave.

Generators Perkins: What servicing and maintenance should I foresee for the Perkins diesel-powered generator models?

Both Perkins diesel and Cummins generators require active maintenance for their efficient operation. Perkins has well documented maintenance schedule that involves periodic changes of oil, oil filters, checks of the fuel components, changing and replacing coolants, as well as regular inspection of belts and hoses. Transmission of generator spare parts could hardly be perceived as any difficulties, as modifying or replacing parts of a generator does not take too much time. Always make sure to restore the correct level of performance of the manufacturer’s engine karts and use only the original equipment manufacturer (OEM) Perkins servicing parts available when possible.

Are Cummins diesel generator sets better for rental power applications?

Cummins provides a lot of generator models that aren’t good for rental power applications simply because of the diesel generators that they provide, which are very powerful and rugged; therefore, they will be very useful as they have high power output. Cummins is also known for dynamic or always unstable load engines, commonly in the center of start-stop or stop-relatively long run patterns. Also, in the industrial sector, Cummins engine applications are limited to rugged territories and are available with a wide range of spares to the users’ advantage and, importantly, to the rental operators on the other hand.

Cummins or Perkins: How many watts should a house generator have?

When it comes to making a decision on the generator to keep running longer, one must look into the details of some factors, which include evaluation of load characteristics, assessment of power to be delivered continually, evaluation of fuel consumption, and assessment of the ease of maintenance. For the full growth of power, there are Cummins models that are well-suited and energy-efficient, and the case is the same with Perkins for generators that are also compact and quiet. For continuous loads, reliability, minimum fuel usage, and local warranty are the major decisions that should be put in place while using the sets of two suppliers.

Perkins vs Cummins generators: Which brand offers less noisy and more compact?

Perkins tries to produce electric generating mechanisms that are convenient, do not make much noise, and aesthetic for such components. As for Cummins generators, the engines they use make them stronger and more economical, but in some cases may become noisier for the large ones unless a soundproof enclosure or attenuation methods are incorporated. Both manufacturers bring out answers to the noise issue, the solutions preferred for the situation when noise and size are the key factors are more inclined to Perkins.

Help you choose: How can I evaluate long-term costs and support when selecting between Cummins and Perkins?

To further discover the long-term costs of diesel generators, a rough estimate can be made by accounting for the purchase price, average fuel economy, service period, projected market, and residual values. They are both Cummins and Perkins respectively regarded as reputable companies, the cost drivers of cummins and perkins engines are quite distinct: Cummins often has a better fuel economy, which in many instances results not only in cutting costs but also in providing adequate after sales services especially in large installations; on the other hand, spare parts at perkins are quite affordable and ease of repair is provided in many cases due to a different design and configuration of the engines. One should contact a local dealer and study the full warranty, and hiring a unit for repairs is quite dangerous on a construction site since it would be detrimental in case of an emergency. When this does occur, since an issue’s abridgment is enforced, there will be fewer contractors available.